MAKING SCREWS.

To all whom it may concern:

Be it known that I, CULLEN WHIPPLE,

of the city and

county of Providence, in the State of Rhode Island, have invented

certain new and useful Improvements in Machinery for Performing Certain

Parts of the Operations Involved in the Manufacture of Wood-Screws, of

which the following is a full, clear and exact description, reference

being had to the accompanying drawing, which makes part of this

specification, and in which—

My invention and improvement relate to the feeder for

screw machinery and consist of three elements, viz: 1st, a trough,

slot, channel or other conduit to convey from a heap of screw blanks

lying promiscuously in all positions, a moving row or series of such

blanks with their heads all arranged in the same direction or

thereabouts. 2nd, a series of grooves in a moving surface carried in

succession past the mouth of the conduit in such manner that each

groove will receive therefrom, as it passes, a blank and carry it off.

3rd, a guard, parallel or thereabouts, to the moving surface and placed

against or near the same to prevent the blanks from leaving the grooves

until they reach the point of discharge into the mechanism provided to

receive them.

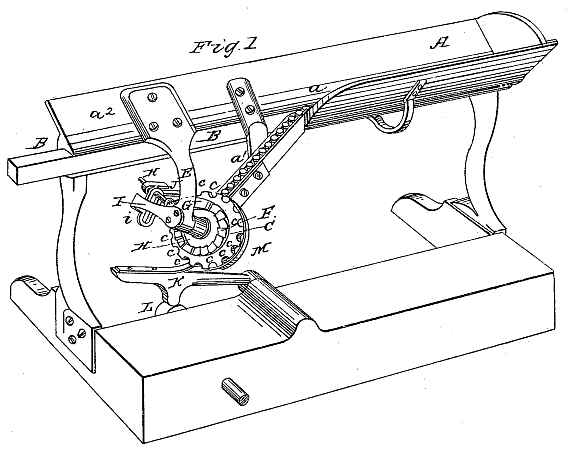

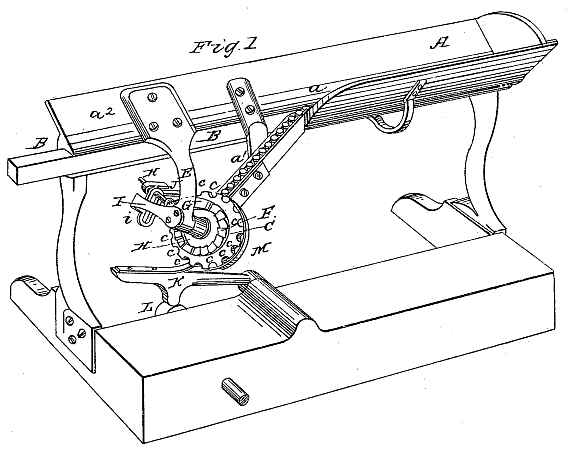

The accompanying drawing represents a portion of a

frame adapted to machinery for shaving, nicking, or threading screws.

This frame is surmounted by a hopper (A) resting on pedestals, to

receive a quantity of screw blanks in promiscuous order ready to be

arranged with their heads in the same direction.

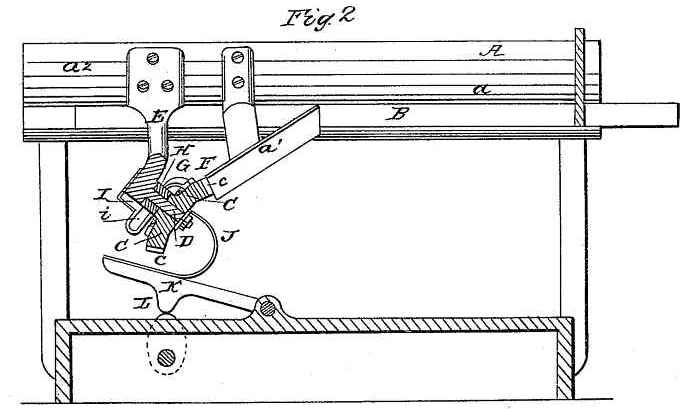

At the bottom of the hopper a horizontal slot (a) is formed that terminates in a second slot (a') which descends at an angle sufficient to permit screw blanks hanging in it by the head to slide freely through it by their own gravity, in a direction from its upper toward its lower end. The horizontal slot (a) should have one or both sides provided with a vibrating bar (B) or roller, or some other contrivance to move the blanks and cause them to advance slowly toward the inclined slot (a').

At the lower end of the inclined slot, a frustum of a

cone (C) is placed. It is mounted upon an inclined spindle (D)

supported by a bracket (E) attached to a prolongation (a2)

of one side of the hopper (A). The axis of the frustum is immediately

opposite the mouth or lower extremity of the inclined slot. The

periphery of the frustum has a series of equidistant grooves cut

therein, converging toward the apex of the cone of which the frustum is

a part. These grooves are of a width, measured on the periphery of the

frustum and in the direction of its circumference, equal in width, to

the mouth of the slot, and their depth is nearly but not quite equal to

their width. On the base or larger end of the frustum, an annular

series of equidistant ratchet teeth (F) are formed, which in number are

equal to that of the grooves (c)

in the periphery.

A ratchet hand (G) to act upon the ratchet teeth and move

the frustum (C) is attached to a vibrating arm (H) hinged on the axle

(D) at the inner end, and at the other end guided and supported in a

slot (i) in an auxiliary

bracket (I). The end of the arm (H) projects through the bracket (I) to

connect with the end of a curved link rod (J) which communicates to it

a reciprocating motion. This link rod is attached to a treadle (K)

actuated by a cam (L) on a shaft below. The curved connecting rod is

made of brass, steel, or other material that possesses the required

elasticity, and should be of such a degree of stiffness that it will

without much flexure press the ratchet hand (G) with sufficient force

to turn the frustum, when the same moves freely; and yet at the same

time, it should be so flexible as to yield sufficiently to allow the

treadle to vibrate without moving the frustum, and thus prevent the

machine from being broken in case the turning of the frustum should

become obstructed. At each advance movement of the ratchet hand (G) one

of the grooves (c) in the

periphery of the frustum is brought opposite the mouth of the inclined

slot (a'), and will receive a

screw blank, which will be prevented from falling out of the groove

after it is carried away from the mouth of the slot, by means of a

guard plate (M) which is arranged parallel to the periphery of the

frustum and extends around the same far enough to bring the blanks to

the desired point of delivery. This guard plate (M) may be supported in

one side of the slot, or by any part of the :frame to which it may be

convenient to attach it.

If instead of a frustum of a cone, a cylinder were used,

the heads of the blanks, because of their larger diameter, would have a

constant tendency to roll forward faster than the points, because of

the head of the blank working partially into the space between the

guard plate (M) and the moving surface. The conical form of the

carrying or moving surface counteracts this tendency of one end of the

blank to advance faster than the other, by making the circle in which

the head travels around the base of the frustum longer than that which

the shank has to travel around its apex in the same proportion as that

part of the surface of the head which rolls on the guard plate is

larger in diameter than the part of the surface of the shank which

rolls on the guard plate. By this means the blank has a tendency to

maintain a position parallel to one of the planes radiating from the

axis of the cone. This grooved frustum resembles a beveled cog wheel,

and may be constructed in the same manner.

What I claim as my invention and desire to secure by

Letters Patent, is—

The combination of the feeding slot, (a a') moving series of discharging

grooves, (c), and guard plate

(M); but I make no claim to either of these elements of the combination

by itself. In testimony whereof, I have hereunto subscribed my name.

Witnesses:

F. G. FONTAINE,

A. E. H. JOHNSON.