To all whom it may concern:

To all whom it may concern:Be it known that I, MICAH RUGG, of Southington, in the county of Hartford and State of Connecticut, have invented a new and useful Improvement in the Mode and Method of Trimming the Heads of Bolts and in the Machinery Necessary for Affecting the Same, and that the following is a full and exact description thereof, reference being had to the annexed drawings, making a part of this specification, in which—

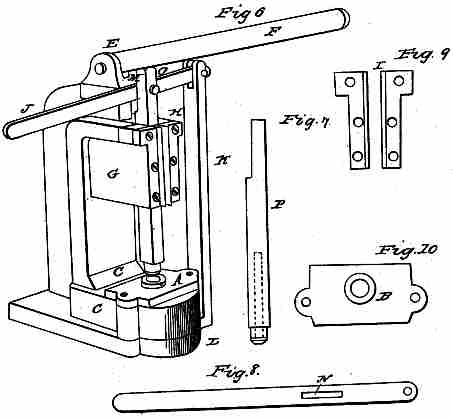

Figure 6 is a perspective view of the machine used for trimming the heads of bolts, a roughness being left upon the edge when the bolt is headed.

The nature of my invention and improvement in this machine consists in having an upright punch or slide with a hole in the lower end of sufficient length to admit the bolt required to be trimmed with the head downward and resting upon a die having a perforation through the same of the exact size of the bolt head when trimmed as may be seen at A in Fig. 6 or B in Fig. 10.

To enable others skilled in the art to make use of my invention and improvement I will proceed to describe the construction, operation and use of the trimming machine, which is as follows: The base or foundation of the machine marked C, on the forward part of which is placed the die with the perforated hole marked A and made part by means of two bolts with nuts running through the base C and die A. From the back part of the case C rises the perpendicular portion of the casting of the machine marked D, on the top of which is cast two ear pieces or projections marked E to receive and hold to its place the lever F by means of a pin or bolt running through both; a forward projection from the perpendicular part or portion of the machine is marked G, having a groove marked H in the perspective to admit the slide or punch 0 in perspective.

In Fig. 9 are two iron plates made fast to the machine by means of screws the use of which is to hold in its proper place and keep steady the slide or punch marked O in perspective. The transverse lever J is attached to a perpendicular post marked K, the bottom of which is made fast to the base of the machine at L. The transverse lever J has a long mortise at M in the perspective and at N in Fig. 8 receiving a pin that passes through the slide or punch O in the perspective and T, Fig. 7, allowing a slide in the movement of the machine that the slide O may be raised and lowered in a perpendicular direction. Fig. 7 represents the slide or punch O with the hole at the bottom to receive the bolt.

Fig. 8 represents the transverse lever J with the mortise.

Fig. 9 represents the iron plates that holds the slide O in the groove H in the perspective.

Fig. 10 represents the die through which the bolt passes when trimmed and marked A in the perspective. In the operation of the machine place the lever F in a perpendicular position, then raise the transverse lever J, by which operation the slide O is raised; place the bolt in the hollow slide O, letting the head rest over the die A. Then by means of the lever F force down the slide or punch O that the head of the bolt may pass through the die A, coming through the under side of the machine with the edges perfectly trimmed off. The slide or punch may be forced through and the bolt trimmed by the use of a screw attached to the slide or by striking on the top with any heavy hard substance or metal sufficiently hard to force through the bolt.

What I claim as. my invention and desire to secure by Letters Patent is—

The combination of the hollow slide or punch which receives and carries the bolt in combination with the die for trimming the heads of bolts as described.