UNITED STATES

PATENT

OFFICE.

JOSEPHINE G.

COCHRAN, OF SHELBYVILLE, ILLINOIS.

DISH-WASHING

MACHINE

SPECIFICATION forming part of Letters

Patent No. 355,139, dated December 28,1886.

Application

filed December 31, 1885. Serial No. 187,276. (No model)

To all whom it may concern:

Be it known that I, JOSEPHINE

G. COCHRAN,

a citizen of the United States, residing at Shelbyville, in the county

of Shelby and State of Illinois, have invented a new and useful

Improvement in Dish-Washing Machines, of which the following is a

specification.-

My invention relates to an improvement

in machines

for washing dishes, in which a continuous stream of either soap-suds or

clear hot water is supplied to a crate holding the racks or cages

containing the dishes while the crate is rotated so as to bring the

greater portion thereof under the action of the water.

The improvement will first be described

with

reference to the accompanying drawings, and then be more particularly

pointed out in the claims.

[Click

on any thumbnail below to enlarge]

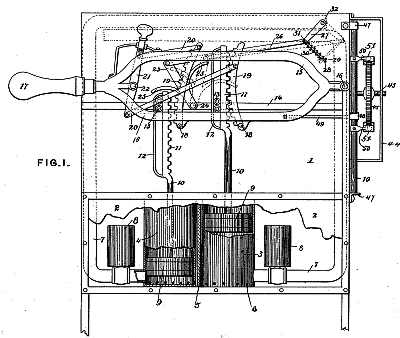

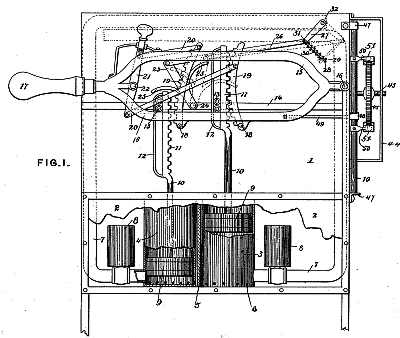

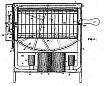

Figure I represents my improved dish-washing machine in front

elevation, parts being broken away to exhibit interior portions. Fig.

II is a vertical sectional view of the same, looking from the opposite

side. Fig. III shows a bottom view and a side elevation of a portion of

the preferred form of the water-spray pipe. Fig. IV is an end elevation

of the crate. Fig. V is a side elevation of the supporting-bracket for

one end thereof. Fig. VI is a perspective view of the driving disk and

shaft of said crate. Fig. VII is a side elevation of the machine, part

of the casing being broken away to show one of the pumps. Fig. VIII is

a detail view of part of the crate-operating mechanism. Fig. IX is a

front elevation, and Fig. X a side elevation, of a rack or cage for

knives, forks, and spoons. Figs. XI to XV, inclusive, are side and end

elevations and plan of two forms of racks or cages for dishes, plates,

&c.

Figure I represents my improved dish-washing machine in front

elevation, parts being broken away to exhibit interior portions. Fig.

II is a vertical sectional view of the same, looking from the opposite

side. Fig. III shows a bottom view and a side elevation of a portion of

the preferred form of the water-spray pipe. Fig. IV is an end elevation

of the crate. Fig. V is a side elevation of the supporting-bracket for

one end thereof. Fig. VI is a perspective view of the driving disk and

shaft of said crate. Fig. VII is a side elevation of the machine, part

of the casing being broken away to show one of the pumps. Fig. VIII is

a detail view of part of the crate-operating mechanism. Fig. IX is a

front elevation, and Fig. X a side elevation, of a rack or cage for

knives, forks, and spoons. Figs. XI to XV, inclusive, are side and end

elevations and plan of two forms of racks or cages for dishes, plates,

&c.

1 may represent a metallic or wooden

box, having a

forward extension providing two tanks, 2, wherein are situated two

force-pumps, 3 4. The lower part of the box is divided into two

compartments for the height of the forward extension 2 by a vertical

diaphragm, 5, one of the pumps 3 4 being situated in each compartment.

This device, with the aid of the movable bottom 36 for box 1,

hereinafter described, enables the complete separation of the water in

one side of the machine from the other, the soap-suds and clear hot

water, when respectively used, being each returned to its appropriate

force-pump and used over and over again until it needs renewing.

6 are apertures for allowing water to

enter the

lower cylinders, 3 4, of the pumps. These apertures may be valved; or a

single valved aperture may be substituted therefor.

7 are water-jet pipes extending from the pumps 3 4 at each side of the

box 1, and terminating at the top in a horizontal portion, which is

either slotted throughout, as shown in, Fig. II, or provided with a

series of jet-holes, as shown in Fig. III.

7 are water-jet pipes extending from the pumps 3 4 at each side of the

box 1, and terminating at the top in a horizontal portion, which is

either slotted throughout, as shown in, Fig. II, or provided with a

series of jet-holes, as shown in Fig. III.

8 are air-cushioning chambers in the

force-pipes 7.

9 are pump-pistons having rods 10,

provided with

racks 11 at their upper ends. Strips 12, cast or formed on the rack 11,

engage over pins or rollers 13, supported from the cross-bar 14 of the

box, and thus guide the piston-rods 10 in vertical paths.

15 is the main operating-lever of the

machine,

pivoted at 16 to the frame of the box, and provided at its other end

with a handle, 17. Pivoted to the lever 15, at 18 18, are two

segment-racks, 19 19, connected by rods 20, near their upper ends, with

the opposite ends of the vertical lever 21, pivoted at 22 to the main

lever 15.

It will be seen that by operating the

small lever 21

either of the racks 19 may be thrown against its appropriate piston-rod

rack 11, the other segment-rack 19 being simultaneously detached. The

lever 15 being then operated, it actuates that pump-piston whose rack

is for the time being engaged by one of the segment-racks 19.

Simultaneously with the shifting of the operating-lever from one pump

to the other, I shift the movable bottom 36, before mentioned, so as to

supply water to the tank 2 at one or the other side of the box. This is

accomplished by the following mechanism:

23 is a lever, pivoted at 24 to the

frame of the

box, and having curved arms 25, which occupy positions over one or

other of the racks 11, so that upon the operation of one of such racks

by the mechanism just described it will at the first stroke, if one of

the arms of the lever 23 be at the time above it, throw the lever 23

over its fulcruming-point 24, and thus allow said rack to reciprocate

without again coming in contact with the arm 25.

26 is a rod connecting the lever 23 with

a crank, 27.

28 is a pin or bolt hinged to the

connection between

the rod 26 and crank 27 at its upper end, and sliding in a bracket, 29,

on the box at its lower end. A spring, 30, surrounding the pin 28 bears

on the bracket 29 and crank 27, so as to insure the throwing of such

crank, and consequently of the lever 23, to its extreme position as

soon as the knuckle-joint at 31 passes to one or the other side of a

straight line drawn between the pivot-pin 32 of crank 27 and the center

of bracket 29. The pivot-rod 32 is rigidly connected interiorly of the

box to a second crank, 33, and thus, by connecting rod 34 with arms 35

of the movable bottom 36, a ledge, 37, is fixed to each side of the

box, immediately over the path of the movable bottom 36, so as to

direct water falling down the sides of the box onto the bottom.

From the above-described construction it

is apparent

that as soon as one or other of the pumps is operated the movable

bottom is automatically shifted from the appropriate side, so that

water is returned to the tank of the pump being used and warded off

from the other tank.

An oil or other stove or heater: may be

placed under

one or other of the tanks 2 2, which it is preferred to employ for

containing the hot water.

38, Figs. II and IV, is a cylindrical

wire crate,

wherein the cages containing the dishes to be cleaned are placed.

39 is a door at one side of the crate, having suitable means of

fastening. (Not here shown.) A circular trunnion, 40, at one end of the

crate 38 is supported in a bracket, 41, Fig.V, which is fixed to the

side of the box and open at top, so as to allow the crate to be readily

removed. At its other end the crate has a square projection or trunnion

for engaging in a similarly-shaped socket, 42, Fig. VI, on the inner

end of a shaft, 43, Fig. II, journaled in the wall of the box and in a

bracket, 44.

39 is a door at one side of the crate, having suitable means of

fastening. (Not here shown.) A circular trunnion, 40, at one end of the

crate 38 is supported in a bracket, 41, Fig.V, which is fixed to the

side of the box and open at top, so as to allow the crate to be readily

removed. At its other end the crate has a square projection or trunnion

for engaging in a similarly-shaped socket, 42, Fig. VI, on the inner

end of a shaft, 43, Fig. II, journaled in the wall of the box and in a

bracket, 44.

45 is a friction-disk fixed on the shaft

43 so as to revolve in a vertical plane.

46 is a vertical rock-shaft journaled in

brackets

47, and having a horizontal crank-arm, 48, connected by rod 49 with the

main operating-lever 15, and having additional horizontal crank-arms,

50, carrying friction-clutches 51. The said clutches engage with

opposite sides of the disk 45 in one direction of their motion and not

the other, so as to alternately grasp and rotate the same.

During the continuous operation of the lever 15, and while one of the

pumps 3 4 is supplying a steady stream of water through the pipes 7 to

dishes in the crate 38, the shaft 46 is by its connection with the

lever 15 rocked, and the disk 45 and crate 38 slowly rotated, so that

all the dishes in the crate are exposed to the stream of water and

cleaned. After they are thoroughly cleaned by soap-suds from one pump,

the racks 11 19 are shifted so as to bring the other clear-hot-water

pump into operation, thus automatically uncovering the proper tank in

the bottom of the box. By this means a stream of hot rinsing-water is

poured onto the dishes until they are perfectly clean. When they are

dry from their own heat they are ready to be put away or immediately

again used upon the table, no draining or drying being necessary after

their removal from the machine.

During the continuous operation of the lever 15, and while one of the

pumps 3 4 is supplying a steady stream of water through the pipes 7 to

dishes in the crate 38, the shaft 46 is by its connection with the

lever 15 rocked, and the disk 45 and crate 38 slowly rotated, so that

all the dishes in the crate are exposed to the stream of water and

cleaned. After they are thoroughly cleaned by soap-suds from one pump,

the racks 11 19 are shifted so as to bring the other clear-hot-water

pump into operation, thus automatically uncovering the proper tank in

the bottom of the box. By this means a stream of hot rinsing-water is

poured onto the dishes until they are perfectly clean. When they are

dry from their own heat they are ready to be put away or immediately

again used upon the table, no draining or drying being necessary after

their removal from the machine.

To strain off the larger impurities a perforated diaphragm may be

placed under the movable bottom of the tank, as shown in Fig. II at 72.

To strain off the larger impurities a perforated diaphragm may be

placed under the movable bottom of the tank, as shown in Fig. II at 72.

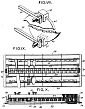

A rack or cage for knives and similar

articles is

shown in Figs. IX and X. It consists of a frame, 52, preferably of

wire, to the end plates, 53, of which are secured the ends of the bars

54, which support a number of spring-clamps, 55. Articles to be washed

are laid upon the bars 56 of the frame, and the clamp-bars 54 are then

placed over them and are held down by the racks 57, engaging with

projections 58 on the ends of the bars 54.

In Figs. XI and XII are shown side and end elevations of a rack for

plates, saucers, &c. The outer web of the cage is made of wires

59,

so as to be practically rectangular. From each corner wire projects

into the case a series of wires, 60, which for the major part of their

length are parallel with the outer wires of the cage, and which serve

as supports for the plates placed in the cage in vertical position.

Frames 61, having vertical wires 62, which may project, as shown, and

may be similar to those 60, may be placed between any two of the wires

60 at the ends of the cage, and thus divide the cage into two parts,

and at the same time afford an interior bearing for the plates and

saucers that are placed within the cage. For articles that require a

spring-support below, an interior cushion is provided in one of the

compartments of the cage, consisting of springs 63, united by

longitudinal and cross bars 64. Handles 65 are provided at each end of

the cage for convenience in carrying.

In Figs. XI and XII are shown side and end elevations of a rack for

plates, saucers, &c. The outer web of the cage is made of wires

59,

so as to be practically rectangular. From each corner wire projects

into the case a series of wires, 60, which for the major part of their

length are parallel with the outer wires of the cage, and which serve

as supports for the plates placed in the cage in vertical position.

Frames 61, having vertical wires 62, which may project, as shown, and

may be similar to those 60, may be placed between any two of the wires

60 at the ends of the cage, and thus divide the cage into two parts,

and at the same time afford an interior bearing for the plates and

saucers that are placed within the cage. For articles that require a

spring-support below, an interior cushion is provided in one of the

compartments of the cage, consisting of springs 63, united by

longitudinal and cross bars 64. Handles 65 are provided at each end of

the cage for convenience in carrying.

Figs. XIII, XIV, and XV are respectively side elevation, plan, and end

elevation of a rack for glass and other hollow articles. The rack or

cage is made of wires 66, and is divided into two parts which are

hinged together, as shown at 67; but they may be fixed so as to form a

rectangular cage by means of catches 68. Within each compartment of

this cage a number of spiral springs, 69, are arranged upon a movable

frame, 70, and so adapted as to surround the necks and bases of hollow

articles, and by pressing them gently against the top and bottom of the

cage hold them in position while the cage is being turned within the

crate of the dish-washing machine. To increase their power of

maintaining the dishes in upright position, the lower ends of the

springs 69 are preferably connected by links 71.

Figs. XIII, XIV, and XV are respectively side elevation, plan, and end

elevation of a rack for glass and other hollow articles. The rack or

cage is made of wires 66, and is divided into two parts which are

hinged together, as shown at 67; but they may be fixed so as to form a

rectangular cage by means of catches 68. Within each compartment of

this cage a number of spiral springs, 69, are arranged upon a movable

frame, 70, and so adapted as to surround the necks and bases of hollow

articles, and by pressing them gently against the top and bottom of the

cage hold them in position while the cage is being turned within the

crate of the dish-washing machine. To increase their power of

maintaining the dishes in upright position, the lower ends of the

springs 69 are preferably connected by links 71.

Having thus described my invention, the

following is

what I claim as new therein and desire to secure by Letters Patent:

1. In combination with the box of a

dish-washing

machine, receptacles or tanks connected therewith and a movable bottom

adapted to cover one receptacle and deflect water falling thereon into

the other, substantially as set forth.

2. In combination with the box of a

dish-washing

machine, an operating-lever, pumps, racks on the piston-rods of said

pumps, pivoted racks supported on the main operating-lever, and means

for throwing one or other of said pivoted racks into engagement with

the rack on one of the piston-rods, substantially as set forth.

3. In combination with the box of a

dish-washing

machine, partitioned as shown, two pumps, means of connecting one or

other at will with the operating handle or lever, a movable bottom for

the box, and connections therefrom to the pump-pistons, whereby it is

automatically shifted as each pump is alternately operated,

substantially as set forth.

4. In combination with the box 1, the

pump

piston-rods and a lever for operating the same, a lever, 23, pivoted to

the box, having arms 25, projecting over the piston-rods, and a movable

bottom wherewith said lever 23 is connected, substantially as set forth.

5. In combination with the lever 23 and

means for

shifting the same, a crank, 27, a rod, 26, connecting said crank and

lever, a movable bottom operated by said crank, and a spring-bolt, 28

29 30, for throwing said crank and lever to its extreme positions to

one side or the other, substantially as set forth.

6. The combination, with a box and

rotary crate, of

two pumps having independent discharge-pipes, a hinged lever adapted to

engage either pump-rod, and a connection, substantially as described,

by which the lever ro-tates the crate while connected with either pump.

7. In combination with a horizontal

rotary

dish-crate, a horizontal shaft connected thereto, a friction-disk

thereon, a vertical rock-shaft carrying friction-clutches engaging with

said disk, and an operating-lever connected with said vertical

rock-shaft, substantially as set forth.

8. In combination with a rotary

dish-crate having a

square trunnion at one end for engaging with the operating-shaft and a

circular trunnion at the other, a bracket fixed to the box having

bearing for the circular trunnion, open at top to permit the removal of

the crate, substantially as set forth.

9. A knife-and-fork rack or cage for

dish-washing

machines, consisting of a frame, 52, provided with end plates, 53,

having racks 57, the bars 54, having projections 58, the bars 56, on

which the articles are placed, and spring-clamps 55, substantially as

described.

10. A plate-and-saucer rack or cage for

dish-washing

machines, consisting of an approximately rectangular wire cage having

an outer web of wires, 59, and the inwardly-projecting vertical wires

60, extending from the corners around the sides and ends, substantially

as described.

11. A plate-and-saucer rack or cage for

dish-washing

machines, consisting of an approximately rectangular wire cage having

an outer web of wires, 59, the inwardly-projecting vertical wires 60,

extending from the corners around the sides and ends, and the interior

frames, 61, having vertical wires 62, similar to the

inwardly-projecting vertical wires, substantially as described.

12. A rack for hollow articles,

consisting of two

wire cages having wires 66, hinged together, means for securing them

together at the front, and movable frame 70, spiral springs 69, and

connecting links 71, substantially as described.

JOSEPHINE G.

COCHRAN.

Witnesses:

J. WM.

LLOYD,

R. L. GARIS.

Figure I represents my improved dish-washing machine in front

elevation, parts being broken away to exhibit interior portions. Fig.

II is a vertical sectional view of the same, looking from the opposite

side. Fig. III shows a bottom view and a side elevation of a portion of

the preferred form of the water-spray pipe. Fig. IV is an end elevation

of the crate. Fig. V is a side elevation of the supporting-bracket for

one end thereof. Fig. VI is a perspective view of the driving disk and

shaft of said crate. Fig. VII is a side elevation of the machine, part

of the casing being broken away to show one of the pumps. Fig. VIII is

a detail view of part of the crate-operating mechanism. Fig. IX is a

front elevation, and Fig. X a side elevation, of a rack or cage for

knives, forks, and spoons. Figs. XI to XV, inclusive, are side and end

elevations and plan of two forms of racks or cages for dishes, plates,

&c.

Figure I represents my improved dish-washing machine in front

elevation, parts being broken away to exhibit interior portions. Fig.

II is a vertical sectional view of the same, looking from the opposite

side. Fig. III shows a bottom view and a side elevation of a portion of

the preferred form of the water-spray pipe. Fig. IV is an end elevation

of the crate. Fig. V is a side elevation of the supporting-bracket for

one end thereof. Fig. VI is a perspective view of the driving disk and

shaft of said crate. Fig. VII is a side elevation of the machine, part

of the casing being broken away to show one of the pumps. Fig. VIII is

a detail view of part of the crate-operating mechanism. Fig. IX is a

front elevation, and Fig. X a side elevation, of a rack or cage for

knives, forks, and spoons. Figs. XI to XV, inclusive, are side and end

elevations and plan of two forms of racks or cages for dishes, plates,

&c. 7 are water-jet pipes extending from the pumps 3 4 at each side of the

box 1, and terminating at the top in a horizontal portion, which is

either slotted throughout, as shown in, Fig. II, or provided with a

series of jet-holes, as shown in Fig. III.

7 are water-jet pipes extending from the pumps 3 4 at each side of the

box 1, and terminating at the top in a horizontal portion, which is

either slotted throughout, as shown in, Fig. II, or provided with a

series of jet-holes, as shown in Fig. III. 39 is a door at one side of the crate, having suitable means of

fastening. (Not here shown.) A circular trunnion, 40, at one end of the

crate 38 is supported in a bracket, 41, Fig.V, which is fixed to the

side of the box and open at top, so as to allow the crate to be readily

removed. At its other end the crate has a square projection or trunnion

for engaging in a similarly-shaped socket, 42, Fig. VI, on the inner

end of a shaft, 43, Fig. II, journaled in the wall of the box and in a

bracket, 44.

39 is a door at one side of the crate, having suitable means of

fastening. (Not here shown.) A circular trunnion, 40, at one end of the

crate 38 is supported in a bracket, 41, Fig.V, which is fixed to the

side of the box and open at top, so as to allow the crate to be readily

removed. At its other end the crate has a square projection or trunnion

for engaging in a similarly-shaped socket, 42, Fig. VI, on the inner

end of a shaft, 43, Fig. II, journaled in the wall of the box and in a

bracket, 44. During the continuous operation of the lever 15, and while one of the

pumps 3 4 is supplying a steady stream of water through the pipes 7 to

dishes in the crate 38, the shaft 46 is by its connection with the

lever 15 rocked, and the disk 45 and crate 38 slowly rotated, so that

all the dishes in the crate are exposed to the stream of water and

cleaned. After they are thoroughly cleaned by soap-suds from one pump,

the racks 11 19 are shifted so as to bring the other clear-hot-water

pump into operation, thus automatically uncovering the proper tank in

the bottom of the box. By this means a stream of hot rinsing-water is

poured onto the dishes until they are perfectly clean. When they are

dry from their own heat they are ready to be put away or immediately

again used upon the table, no draining or drying being necessary after

their removal from the machine.

During the continuous operation of the lever 15, and while one of the

pumps 3 4 is supplying a steady stream of water through the pipes 7 to

dishes in the crate 38, the shaft 46 is by its connection with the

lever 15 rocked, and the disk 45 and crate 38 slowly rotated, so that

all the dishes in the crate are exposed to the stream of water and

cleaned. After they are thoroughly cleaned by soap-suds from one pump,

the racks 11 19 are shifted so as to bring the other clear-hot-water

pump into operation, thus automatically uncovering the proper tank in

the bottom of the box. By this means a stream of hot rinsing-water is

poured onto the dishes until they are perfectly clean. When they are

dry from their own heat they are ready to be put away or immediately

again used upon the table, no draining or drying being necessary after

their removal from the machine. To strain off the larger impurities a perforated diaphragm may be

placed under the movable bottom of the tank, as shown in Fig. II at 72.

To strain off the larger impurities a perforated diaphragm may be

placed under the movable bottom of the tank, as shown in Fig. II at 72. In Figs. XI and XII are shown side and end elevations of a rack for

plates, saucers, &c. The outer web of the cage is made of wires

59,

so as to be practically rectangular. From each corner wire projects

into the case a series of wires, 60, which for the major part of their

length are parallel with the outer wires of the cage, and which serve

as supports for the plates placed in the cage in vertical position.

Frames 61, having vertical wires 62, which may project, as shown, and

may be similar to those 60, may be placed between any two of the wires

60 at the ends of the cage, and thus divide the cage into two parts,

and at the same time afford an interior bearing for the plates and

saucers that are placed within the cage. For articles that require a

spring-support below, an interior cushion is provided in one of the

compartments of the cage, consisting of springs 63, united by

longitudinal and cross bars 64. Handles 65 are provided at each end of

the cage for convenience in carrying.

In Figs. XI and XII are shown side and end elevations of a rack for

plates, saucers, &c. The outer web of the cage is made of wires

59,

so as to be practically rectangular. From each corner wire projects

into the case a series of wires, 60, which for the major part of their

length are parallel with the outer wires of the cage, and which serve

as supports for the plates placed in the cage in vertical position.

Frames 61, having vertical wires 62, which may project, as shown, and

may be similar to those 60, may be placed between any two of the wires

60 at the ends of the cage, and thus divide the cage into two parts,

and at the same time afford an interior bearing for the plates and

saucers that are placed within the cage. For articles that require a

spring-support below, an interior cushion is provided in one of the

compartments of the cage, consisting of springs 63, united by

longitudinal and cross bars 64. Handles 65 are provided at each end of

the cage for convenience in carrying. Figs. XIII, XIV, and XV are respectively side elevation, plan, and end

elevation of a rack for glass and other hollow articles. The rack or

cage is made of wires 66, and is divided into two parts which are

hinged together, as shown at 67; but they may be fixed so as to form a

rectangular cage by means of catches 68. Within each compartment of

this cage a number of spiral springs, 69, are arranged upon a movable

frame, 70, and so adapted as to surround the necks and bases of hollow

articles, and by pressing them gently against the top and bottom of the

cage hold them in position while the cage is being turned within the

crate of the dish-washing machine. To increase their power of

maintaining the dishes in upright position, the lower ends of the

springs 69 are preferably connected by links 71.

Figs. XIII, XIV, and XV are respectively side elevation, plan, and end

elevation of a rack for glass and other hollow articles. The rack or

cage is made of wires 66, and is divided into two parts which are

hinged together, as shown at 67; but they may be fixed so as to form a

rectangular cage by means of catches 68. Within each compartment of

this cage a number of spiral springs, 69, are arranged upon a movable

frame, 70, and so adapted as to surround the necks and bases of hollow

articles, and by pressing them gently against the top and bottom of the

cage hold them in position while the cage is being turned within the

crate of the dish-washing machine. To increase their power of

maintaining the dishes in upright position, the lower ends of the

springs 69 are preferably connected by links 71.