To all whom it may concern:

Be it known that I, ALLEN B. WILSON, of Watertown, in the county of Litchfield and

State of Connecticut,

have invented certain new and useful Improvements in Sewing-Machines;

and I do hereby declare that the following is a full clear, and exact

description of the same, reference being had to the accompanying

drawings, forming part of this specification, in which—

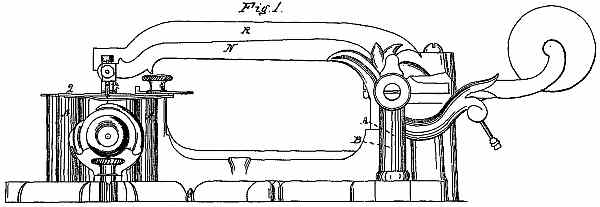

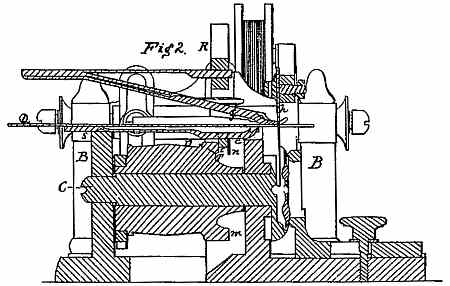

Figure 1 is a side elevation of the machine; and Fig. 2 is

a transverse

vertical section of the same, taken through the parts which form the

stitches, and represents the peculiar arrangement for feeding the cloth

along, in which said improvements consist.

To enable those skilled in the art to make and use my

invention, I

will describe its construction and operation.

The working parts of the machine are all attached to or

carried by a

suitable framework, A A B B, which is secured firmly to a table or

bench. The mandrel C, resembling in a certain degree the mandrel of a

lathe, is fitted in suitable bearings in the framework A A B B, and is

suitably turned or provided with a pulley, D, to receive the rotary

motion, through a driving-band, from a driving-wheel moved by a

treadle under the table, or by any suitable means.

The operative parts of this machine and its construction

are

substantially the same as those described in Letters Patent of the

United States, bearing date the 15th day of June, A. D. 1852, granted

to Nathaniel Wheeler, A. B. Wilson, Alamson Warren, and S. P.

Woodruff, of Watertown aforesaid.

The material to be sewed is laid upon a plate, Q, which is

secured to

the standards A A, and forms a small table. It is held down by a small

pressing-spring, which is attached to the end of an arm, R, which is

secured to the back of the frame-work, and extends over the top of the

machine. In the front end of the pressing-spring f there is a slot, g,

cut to allow the needle to pass through. An opening corresponding to

the slot g, is cut through

the plate Q for the same purpose.

The arrangement for feeding the cloth along is shown in

Fig. 2,

and

consists of a feed-bar, S. It is a straight flat bar with a slot

extending nearly its whole length and with a projection, i, downward.

Under the slot is secured a spring-bar, k, which is furnished with

pointed teeth or notches at the end. The bar S slides in suitable

bearings in the frame B B, immediately below the plate Q. The teeth or

notches of the spring-bar k

are immediately under a small opening in

plate Q, but do not arise through this opening until pressure is

applied to the spring-bar k

by the revolution of the cam T upon the

mandrel, which cam is nearly cylindrical and concentric to the

mandrel; but at one point in its periphery there is a prominence. This

prominence extends also to the front. By the revolution of the mandrel

the prominence of the cam is made to act on the under side of the

spring-bar k and force up its

teeth or notches in contact with the

cloth at the same time that its front part acts on the projection i and

moves the feed-bar longitudinally forward toward the plane of the

needle's motion, carrying the cloth with it. The movement of the

feed-bar while its points or notches are above the surface of the

plate Q and in contact with the cloth causes the cloth to move forward

the proper distance for a stitch at each ascent of the needle, the bar

being returned by the pressure of the spring n; attached to the

frame-work, against the projection i

after the prominence m on the

cam

has passed, the notches or teeth being freed from the cloth as soon as

the prominence of the cam is clear of the spring-bar, by the force of

the spring portion of said bar.

What I claim as my invention, and desire to have secured

to me by

Letters Patent, is—

The device above described in a sewing-machine for feeding

the Cloth

along, consisting of a bar furnished with points or notches; having a

vertical or up-and-down motion for fastening the cloth upon and,

releasing it from said bar by striking it against a plate or spring,

and a lateral motion or motion forward and back for feeding the

cloth

along after each stitch, substantially as above set forth.

ALLEN B. WILSON.

Witnesses:

HENRY

BRONSON,

FREDK.

HURD.