(source)

(source)

|

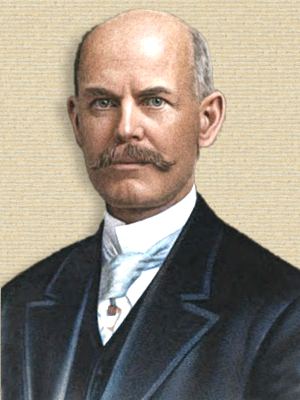

Edward Goodrich Acheson

(9 Mar 1856 - 6 Jul 1931)

American inventor who discovered the abrasive carborundum, the second hardest substance (next to diamonds) and later perfected a method for making graphite. He established the Carborundum Company (1894), to make grinding wheels, whetstones, and powdered abrasives.

|

THE MANUFACTURE OF GRAPHITE.

Engineering and Mining Journal (1899).

By E. G. Acheson.

As the result of my investigations and deductions, I think the only commercial way to make graphite is by breaking up a carbide by the action of heat. The carbon should be freed from chemical combination by what might be termed the evaporation of its associated elementary substances. I have secured patents covering this method, and these have been made the basis for the organization of the Acheson Graphite Company. The company has now under way the erection of works at Niagara Falls, where the necessary electric current will be obtained from the Niagara Falls Power Company.

Several distinct forms of the product will be produced. One consists of forms or articles, made out of amorphous carbon, with the desired amount of impurity added thereto, which will afterwards be heated in an electric furnace and converted, more or less, into graphite. I have been carrying on this line of manufacture for a year or more, using the furnaces of the Carborundum Company to produce the graphitization, the articles having first been made by the arc-light carbon manufacturers. Over 200,000 carbon electrodes, measuring 15 in. in length, with about 1 in. cross-sectional area, were made for us in the Castner alkali process, nearly one-half of them having been shipped to Europe, to be used for this work in England and Germany. The life or efficiency of these graphitized electrodes is many times that of the same electrodes ungraphitized. I have also graphitized some tons of carbon plates, to be used in making dynamo and motor brushes, and a large variety of odd forms and sizes for divers purposes.

Another product—the one which will probably be of greatest importance is an intimate mixture of pure amorphous carbon and graphite in fine powder. This will be put on the market for paint and foundry facing, and, as it has been formed at an extremely high temperature, it is quite pure and possesses all of the qualities desirable for the purposes for which it is intended.

It is not the present intention of the company to enter into the manufacture of this product into finished form for the general market, but rather to encourage those who are now engaged in making up the natural graphite into articles of commerce to become buyers of their material, substituting it for that now used.

The company’s plans, now being carried out, provide for the erection of a brick and iron building, 100 by 50 ft., on the Niagara Falls Power Company’s lands (adjoining the works of the Carborundum Company). Therein it will erect machinery for reducing coke to grains of the desired size, an electric furnace through which the prepared grains will pass in a continuous stream, a pulverizer for reducing the grains as received from the furnace, and a scalping sieve through which the product from the pulverizer will pass, that particles exceeding the 1/200 of an inch diameter may be removed. The final flour or powder will contain an amount of pure graphite proportionate to the percentage of impurities in the original coke. It is quite possible that, instead of using high-grade, marketable coke, the fine refuse from the coke ovens, which is at present a waste material, will be utilized in the manufacture of this product.

In this connection I would call attention to the need of a specific name for the new product. Artificial, as applied to a product, chemically and physically identical with that made by nature, is not pleasing; it conveys the impression that, failing to produce the real thing, a cheap imitation, a sham, is being palmed off as the genuine article. The same objections may be made to the expression artificial manufacture of graphite, which would be quite appropriate were it not for the fact that it is popularly applied to articles made of graphite.

It may not detract from the general interest in this subject to call attention, in closing, to the fact that graphite, first shown to be an elementary body, an allotropic form of carbon, in the first year of the nineteenth century, is in this, the last year, made to order in great quantities, and that it will, before the close of the century, become an article of ordinary commerce in its new form. Perhaps it will take its place as the primitive form of carbon—the one it assumes under normal conditions.

- 9 Mar - short biography, births, deaths and events on date of Acheson's birth.