(source)

(source)

|

Robert Kennedy Duncan

(1 Nov 1868 - 18 Feb 1914)

Canadian industrial chemist, teacher and populariser of science who was a preeminent writer interpreting science and advocated partnering scientific research and industry to create new and better consumer products. As director of the Mellon Institute of Industrial Research he brought the learning of the university to the service of industry.

|

BREAD

Chapter VIII from Some Chemical Problems of Today (1911)

by Robert Kennedy Duncan

[p.143] “No man shall take the nether or the upper millstone to pledge: for he taketh a man’s life to pledge.”—Deut. xxiv: 6.

THESE words signify in a beautiful and very practical way the universal and enduring need of bread. Today, with exceptions so few that they horrify us to hear of, every man, woman, and child in America has his daily wheaten loaf. This wheaten loaf is the evolutionary product of innumerable centuries of baking.

The question, “When did man first eat bread?” might almost as well be answered by another, “When did man first obtain his molar teeth?” The ancient words “bread,” “barm,” “leaven,” “loaf,” “knead,” “lord,” and “lady” signify in their ultimate derivations the immense antiquity of the art of baking; in fact, the making of bread, together with the tanning of skins and the burning of pottery, is one of the oldest of earth’s arts.

The housekeepers of America today make seventy per cent. of all the bread, yet the remaining thirty per cent. made by the bakers involves a capitalization of over

two hundred and seventy millions of dollars. [p.144] Anything, then, that we can discover of the present-day status of the art of bread-making is of importance and of interest. The first known making of bread refers back to the prehistoric lake-dwellings of Europe, where there have been discovered the grains of barley, oats, rye, and wheat, together with the charred remains of cakes of bread and the rude stone grain-crushers and mealing-stones. It is true that these pellets of wheat and barley are but humble representatives of the highly bred grains that now glorify the farmer’s field, and it is true, too, that the loaves were for the most part but of crushed grains, not true meal, and obviously made by being laid on the hot stones and covered over by glowing ashes, just, in fact, as the muleteers of Syria today make their unleavened cakes; but it was bread. Since in Eastern countries a mixture of meal and water will begin to ferment in the course of a day, the value of leavened bread must inevitably have been discovered prior to civilization. We all remember the story of the flight of the Israelites out of Egypt, how “the people took their dough before it was leavened, their kneading-troughs being bound up in their clothes upon their shoulders” (Exodus xii: 34); leavened bread —i.e., bread as we know it—must at that time have been universal. Early, too, must have been the specialization of the art of baking; first, doubtless, in the largest households, as witness the interesting story of that most unfortunate chief baker in Genesis xl; and afterward, [p.145] as the reader may readily find, into a definitely segregated trade, as in Hosea vii.

There have always been bakers, but, on the other hand, from the beginning of human time bread has always been baked in the home, particularly and definitely as the vocational duty of women. There thus appears this most curious and interesting of facts: that contemporaneous with the history of man from the earliest to the latest times there has been an unremitting conflict between home-made bread and the baker’s loaf. The present-day outcome of this eternal war may be expressed in the fact given above: that the housekeeper make seventy percent. of American bread. But how much does this depend upon the traditional enmity of woman toward the baker, and how much upon the traditional timidity of paterfamilias in expressing an opinion upon so delicate a subject? The interests of truth, however, and because it is a subject of such importance to every home, insist that some comparison shall be made between home-made bread and the baker’s loaf.

The traditional idea of the bakery is that of dark, low-ceilinged, germ-laden rooms, in which men, wholly indeterminate in their periods of ablution, swelter among the flour, yeast, and dough, mixing, baking, and pawing over a crude substance adulterated with alum and wholly abominable when compared with the inviting, wholesome aliment of the home. Nothing could be farther from the present-day truth. The bakery, as we shall picture it [p.146] here, does not represent the very best practice and, of course, by no means the worst; it does, however, represent good practice rapidly extending into universality.

The present-day bakery, then, is represented by a large, four-storied, modern building, with asphalted floors. In many rooms its walls are tiled, and in others they are lined with cork to produce equality of temperature. It is provided with beautiful enginery in its power-room, with a cold-storage plant and a cold-air plant.

Let us swiftly review the process. The flour is emptied into the hoppers in the basement, from which it is carried by conveyors to the fourth floor, where, after being vigorously sifted, it passes into a gigantic bin holding, say, seventy-five barrels. The descent of this flour floor after floor marks its transformation into bread. It is automatically withdrawn from the bin, automatically weighed, and automatically dropped into the mixing-machine. In this mixing-machine, with the requisite quantities of yeast, sugar, salt, milk-powder, and malt—if it is used—it is rapidly lashed into a homogeneous dough and subsequently automatically thrust into the fermenting-tanks; from the fermenting-tanks through hoppers down to the cutting-table below; from the cutting-table below through the various cutting-machines, forming-machines, and balling-machines; through the “proof-room” to the oven; and subsequently from the oven to the delivery wagons. The [p.147] words “automatically treated” must be understood as applicable in a large and generous sense. While it is not true that in the practice here described bread is absolutely free from the touch of a human hand, it is almost true; and to such an extent that it is obvious that in the best baking practice of the immediate future this ideal will be completely realized. The process is absolutely flawlessly clean.

Now, as for the materials. These are of the best. The flour is of the best brands, just such, in fact, as the householder uses, and so are the materials. While it is true that generally milk-powder is used instead of milk, and cottonseed oil instead of butter, these materials are clean, pure, and good for the purpose.

And what about the product? Compared with the bread of our grandparents’ time, modern baker’s bread of the best practice is certainly superb. The old-fashioned baker’s loaf that was more holes than bread, and that modicum of bread of a tasteless, indigestible character, has been displaced by a loaf which in color, texture, flavor, and nutritious qualities is positively good.

But not best. Let us grant at once that the very best product of the very best housekeeper (pace uxoris mea) excels in its excellences the best baker’s loaf. But in this production there is no regard for cost either of time or money. If such a housekeeper were to count into the cost factors such as time employed, wear and tear, investment, fuel, failures in her product, stale bread, [p.148] and the prices and quantities of her flour, sugar, milk, and shortening, she would find its summation almost in excess of the price she would pay the baker. As for the average home-made bread, where temperatures are not controlled and qualities of constituents vary, it may assuredly be pronounced no better than the best baker’s bread, as obtainable in large cities. Outside of the instance in which high art and regardlessness of cost figure, home-made bread may be said to pay, possibly, in the case of a mother of a large family who bakes her own bread. As a statement of simple fact, home-made bread must ultimately disappear before the increased efficiency of the baker, the growing accentuation of the servant problem, and the spread of co-operative principles in housekeeping; the bakers will make the bread just as other manufacturers now make the pickles and the mustard and the butter.

Has the best bread been made either in the home or in the bakery? Certainly not. Both in the home and in the factory baking is practised essentially as an art. It has still to become a science. In saying this the large bakers will not agree with me. They will point with triumph to the thermometer which every good baker carries about with him, to the rigorously exact weighing of materials, and to the sternly regulated periods of mixing, fermenting, and baking, and the uniformity of their product. But these statements convey all they have to show of progress. In fact, the bakers, as with [p.149] certain other manufacturers, in standardizing their process are in danger, so to speak, of crystallizing it. They are not themselves, except dimly, aware of the scientific possibilities of their art.

In order to see not only how true this is but how interesting are the problems in themselves, let us review the process. Baking is concerned with some of the most recondite problems in contemporary science.

First, there is the flour. Two flours may be identical to all appearance in color, smell, feel, and granulation, and yet one will make a fine, light, large loaf, and the other a poor, heavy one. It must strike the reader, in view of the hundreds of millions of dollars involved, that it is an important and regrettable fact that neither the baker, the miller, nor the man of science can tell just why—yet so it is. The difficulties involved in answering such a question depend upon the complex nature of flour. Flour contains starch, gluten, sugar, soluble albuminous bodies, fats, oils, mineral matters, such as phosphates, fermenting enzymes, and bacteria. Variations in the quantities of starch in the flour doubtless do affect the quality of the bread, but to a minor extent. The gluten is more important; it is, in fact, certain that the quality and flavor of the bread depend upon the gluten of the flour. And yet how difficult it is to understand!

Gluten is a highly nitrogenous, tough, sticky, elastic material which shows its characteristics only when the [p.150] flour is made into dough. As the dough rises to the baking temperature it puffs itself up into a round ball which sets on the outside into a hard skin or crust, while within, owing to the steam, it lies in a system of fine threads and meshes, in the interstices of which, in the bread, lie the granules of starch. The ability to make a loaf of bread at all evidently depends on the fact that the elastic, sticky gluten at a lower temperature resists the escape of the gas evolved during the fermentation, and so becomes puffed up into lightness, while at a higher temperature it becomes converted into digestible material and sets.

This is the philosophy of baking, but as with other philosophies, it is but the beginning of our explanations and our troubles. If the rising power of the bread depends on the per cent. of gluten in the flour, the flours of maize, barley, and rice ought to make good bread, for they contain more gluten than does wheat. Such flours, however, will not make bread. Evidently, then, what is gluten in one flour is not gluten in another, and evidently, too, we do not know what gluten is. About it, however, this much is known, that the glutens from rye, maize, rice, barley, buckwheat, and wheat all contain varying quantities of two substances, chemically combined or mechanically mixed, nobody knows, called respectively gliadin and glutenin. It turns out, too, that among the grains grown by man wheat contains by far the highest per cent. of gliadin. Gliadin is a very [p.151] sticky substance, while glutenin is not; glutenin, however, seems to form a network to which the gliadin adheres, and the two together, like a concrete of which the gliadin is the cement, seem to constitute the framework of the loaf. Why, then, should not the baker say that the size of his loaf depended upon the relation between the gliadin and glutenin of his flour, and buy his flour accordingly?

The idea was fascinating in its simplicity, but it was based on too restricted a purview. It is partly true, but as a complete explanation it is fallacious. You see, flour is so complex. Every flour contains naturally between one and two per cent. of sugar. This sugar it is, as we shall see, that the yeast utilizes in the fermentation of the dough and out of the destruction of which the gas is produced. It has been discovered that the volume of the loaf depends on the quantity of sugar available during the final stages of fermentation, and hence it has been inferred that the strongest flour is that which has the highest per cent. of natural sugar; this is partly true, perhaps fallacious also, as a complete explanation. Still again, flour contains varying quantities of soluble albuminous bodies, as well as small quantities of fats and oils and mineral matters such as phosphates, and finally of fermenting enzymes, all of which influence not only the size of the loaf, but, as well, the quality, flavor, and texture of the resulting bread.

Obviously the baker does not know how to buy his [p.152] flour. In order to better his flour he, or the miller for him, frequently blends it, and thereupon new troubles begin. By mixing flours it is undoubtedly impossible to regulate one factor without sending topsy-turvy half a dozen others. Moreover—and this is a strange thing —by mixing flours the baker does not get a summation of the qualities of each, but, on the contrary, a completely different flour. The reason for this is absolutely outside the reach of contemporary knowledge. Is it, then, to be wondered at that the baker is virtually compelled to buy his flour in quantities of from one hundred to two hundred thousand barrels at a time without any prior chemical understanding of the validity of his purchase? He depends, with the possible exception of a crude baking test, absolutely on the character of the miller, and the miller—is the miller. When into this mass of flour he places his yeast innumerable additional difficulties flock about his head.

Yeast? From the time of Pasteur it has been the subject of innumerable investigations, and as yet, even today, we are but on the fringe of knowledge. This is particularly true as regards the ferment for bread; for, while millions have been spent on the chemistry of fermentation, this fermentation has had to do essentially with beer and wine; bread has shared only the incidentals of the investigations. Still, to-day, the interests involved in the manufacture of yeast are highly specialized. Particularly is this the case with the [p.153] Netherland Yeast Company, whose factory efficiency it is a privilege to inspect. To the seat of this company at Delft come from all parts of the world maize, barley, and rye. The rye is made to undergo a fermentation which develops lactic acid together with considerable quantities of sugar. This lactic acid-sugar mixture is then used as the medium upon which the parent yeast is grown. While the sugar of the mixture affords food for the yeast, the lactic acid constituent acts as an antitoxin to the various poisonous and bad yeasts and ferments which would normally develop. Meanwhile there has been prepared the immense mixture of saccharine materials, maltose, dextrine, etc., resulting from the action of the malted barley upon the corn; and into this mixture is thrown the selected yeast. There results an immediate fermentation on a huge scale. The yeast is thrown off as a great mass of scum, which is filtered free of water, dried, packed, and sent to the bakers. The liquid mixture, the alcohol, makes its way into gin or into the denatured alcohol of commerce. What goes to the bakers under this process is a mass of innumerable millions of globular organisms, so small that five thousand of them placed in line would barely measure an inch. Everybody knows the essentials of their action. They convert the sugar of the dough into carbonic acid and alcohol, and at the same time there are formed small quantities of glycerin and oxalic acid. The carbonic-acid gas puffs up the dough into lightness, [p.154] the alcohol has a similar effect in the oven, and in addition checks to a slight extent bacterial fermentation, and, as well, has a softening effect upon the gluten of the dough, thus increasing its power to hold the gas which is produced. The bodies of these little organisms contain invertase, which is able to convert sugar-cane into invert sugar; they contain zymase, which is the substance that transforms the sugars so produced into the large quantities of carbon-dioxide and alcohol; and they contain, as well, certain other ferments that convert the protein matter of the bread into material of grateful taste and nutriment. The yeast organisms do not carry out this work per se, but because of these substances they contain. In order that they may rapidly multiply to efficient working, the dough contains, almost providentially one might say, the requisite substances— soluble proteids to afford them nitrogenous food, sugar, without which they will not work at all, and mineral substances which accelerate their action. All this is very pretty philosophy, what we know of it, but, as a matter of fact, the very outposts of a true knowledge of bread-making still remain unconquered.

There are many different strains of yeast; what are the best for the bread concerned? What is the nature of the best soluble proteids for yeast-food, and what should be their proportionate quantity? What mineral substances best accelerate the action of yeast? What is the actual action of yeast in the gluten? What is [p.155] unquestionably the proper temperature of bread fermentation? What is the best method of exorcising the influence of maleficent bacteria and of accentuating or utilizing the influence of bacteria that are beneficent?

All these and many other questions must be answered before we shall know even the causes that produce the highest nutriment, the texture, the crumb, the flavor, or even the bloom on the crust. It is apparent that we are still far from the ambrosial confection of the future.

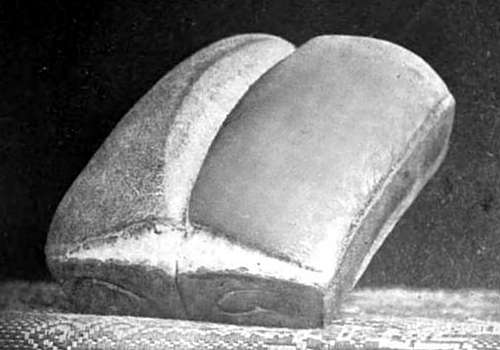

Meanwhile, science is eagerly desirous of obtaining an entrance into these most difficult problems. In this connection it is a particular pleasure to refer to the results obtained by the National Association of Master Bakers’ Fellowship in Industrial Research, established at the University of Kansas. This fellowship, yielding five hundred dollars a year for two years, together with an additional consideration, was conferred upon Mr. H. A. Kohman. During its tenure Mr. Kohman has made himself favorably known to every progressive baker in the United States. His first achievement dealt with the problem of stale bread, which in the case of many bakers amounts to as much as eight per cent. of their output. This stale bread today is sold from one to two cents per loaf. Mr. Kohman evolved the idea of treating this stale bread with small quantities of malt extract, by which its starchy constituents are converted into fermentable sugar. After treatment with the malt, it is [p.156] filtered off and the sugar and the malt together used in the next batch. Mr. Kohman thus, in large measure. saves and eliminates the use of sugar-cane by the baker. He has left behind, as residue of the loaf, all the gluten, in the form of a beautifully pure and pleasant substance. When he has found a practical use for the enormous quantities of gluten thus obtained he will have transformed the stale bread from a loss into a profit. Next, he has discovered, isolated, and grown pure cultures of the bacterium concerned in the fermentation of salt-rising bread. He has grown this pure culture in large quantities, and he has made in his laboratories salt-rising bread of perfectly uniform quality day after day. Finally, he has taken his process and ferment down into one of the largest wholesale bakeries of the United States, and he has turned out the bread resulting from this process, at the rate of a thousand loaves a day, into the market in order to test it. The market received it gladly and without one instance of objection. To any one who understands the past hopelessness of attempting to make salt-rising bread on a large scale, this is a most notable achievement. This salt-rising bread, which in many sections of the South and West is the only bread, has its devotees everywhere, from Governor Stubbs, of Kansas, who offered his daughter a prize of fifty dollars to make it, to the many senders of the letters to the Department of Industrial Research, eagerly requesting samples of the ferment. In the past the [p.157] housekeeper who could make good salt-rising bread had a great reputation; now anybody may make it, and of uniform quality. It is intensely interesting that this splendid “old-fashioned” bread should be due not to yeast at all, but to a specific spore-bearing bacillus—and that this bacillus, dragged out of the empty air, should be in the future a marketable and useful commodity and the basis of a new industry. Figs. 33, 34.

Contributions to the chemistry of bread are now appearing in the journals of science with ever-increasing frequency—many of them interesting and promising of future results. One investigator has been studying the cause of the color in brown bread, another the survival of pathogenic bacteria in bread after baking, still another the proteolytic ferments of wheaten flour and their relation to baking value. Much investigation is being given to-day to the perplexing problem of methods of estimating the strength of flour, and still more, perhaps, to the determination of the relative nutritive values of different kinds of bread. In the Patent Office particularly one finds a special activity in the elaboration of “queer” breads and medicinal breads—breads containing iron, albuminous breads, and breads made up with an attempted regard only for nutritive values. An apparently favorite method of making albuminous bread is to mix with the flours of wheat and rye large quantities of boiled fish and potatoes, after which, as a dough, it is fermented and baked. A new flour appearing in some [p.158] patents consists of the meal of the sweet-potato, banana, and cassava. Out of the many investigations in progress one is impressed with the idea, hardly more than nascent as yet, of the possibility of altering bread into, or adding to it, substances of medicinal quality. By all odds the greatest present-day investigation relates to the permissibility of the process of bleaching flour with substances such as ozone and oxides of nitrogen. Is it harmless or is it vicious? Large interests are involved, and the whole investigation illustrates typically and most regrettably the fact that too often on the receipt of large remuneration the man of science is unable to see with an eye single to the truth. As for the young chemist, seeking for an arbeit, he may find in the bread he daily eats the chemical investigations of a lifetime.

But if men of science are becoming interested in bread, so, certainly, are the bakers. It is true sometimes, as with men of science, their material interests blind them to simple fact. This is notably the case in “the wrapped bread” question which has wrought the trade into a turmoil. To the consumer it would seem an obvious desideratum that the purity of his product should be insured by a wrapping of impervious paper at the bakery itself. The trade is divided on the subject, one side maintaining the validity of the advantage, and the other that, by wrapping, the flavor of the bread is impaired. In order to test the matter the writer fed [p.159] samples of their bread, wrapped and unwrapped, to three representative bakers, and as they were positively unable to detect the slightest difference in either flavor or quality it seems plain that wrapped bread has come to stay. Of course the actual reason for the objections lies in the fact that it costs about 7 per cent. of the selling price of the loaf to give it this impervious wrapping, and that this would mean a corresponding decrease in the size of the loaf. But the whole collegium pistorum, so to speak, is interestingly illustrative of the psychology of trades. As a class they are curiously alike, and differentiated from the followers of other trades as men of quiet diligence, deeply religious, sincere, and idealistic. To the aspirations of the bakers to better and ever better practice their trade journals bear ample witness. But to harry the bakers has always been a favorite game. The statute-books, from the remotest time and in all countries, have sternly and minutely governed the baker, the materials and quantities he should use, how he should bake his bread, what should be the size of the loaf, its price, and where and to whom he should sell it. Witness this old fragment from an Act of Council at Glasgow; it is typical of hundreds of others:

“And it sall not be lesum to nayne traweller that brings breid to the mercat to sell ye samyn to nayne outtentowneris man in laides [loads], crieles [baskets], nor half crieles jumgit ye gedder [in heaps] quhile the inhabitants of the towne be first servit, and XII houris struken, and that na man of man sell the breid that [p.160] is brocht to the towne bot the bringar of the same allanerlie [alone], and that na traweller bring breid to ye towne to sell but IIIId breid and twapenny breid,” etc., etc.

In these days, however, the restrictive panary laws that have been passed in many States and localities are only too often unduly onerous and essentially unjust. The fact that bread is the staff of life is particularly unfortunate for the baker in making him a popular target for legislative enactments. But it should be remembered that the baker with his loaf is at the beginning of a procession leading back to the land. There is the farmer with the prices of his agricultural machinery and his labor—the railroad with its transportation rates—the grain-elevator—the miller—the stock manipulator—the commission merchant—the yeast people—and for the baker himself the increased prices of his labor, power, and machinery. All such on a constantly rising scale of cost must be satisfied before the baker receives his modicum of profit—and the profit is certainly not excessive. Did the reader ever see a really rich baker? There are not many such, for large returns rest wholly on a tonnage basis. If the prices of material, labor, and power continually rise, the price of the loaf must rise with them, or the size of the loaf must decrease; there is no other solution, “For the Scripture saith,‘Thou shalt not muzzle the ox when he treadeth out the corn, and the laborer is worthy of his hire.’”

- Science Quotes by Robert Kennedy Duncan.

- 1 Nov - short biography, births, deaths and events on date of Duncan's birth.

- Harnessing Science to the Factory - article about the Mellon Institute of Industrial Research at the University of Pittsburgh, conceived by Robert Kennedy Duncan - from Popular Mechanics (1914.

- Camphor: An Industry Revolutionized - Chapter from Some Chemical Problems of Today (1911), by Robert Kennedy Duncan.