(source)

(source)

|

Ottmar Mergenthaler

(11 May 1854 - 28 Oct 1899)

German-American inventor who invented the Linotype machine which revolutionized typesetting, enabling one operator at a keyboard to do the work of three men setting moveable type. The machine cast each line as a bar.

|

The Linotype.

A MACHINE WHICH SUPERSEDES TYPE-SETTING AND DISTRIBUTION, AND DISPENSES WITH MOVABLE TYPES.

The somewhat lengthy title to this article is made necessary in order to convey to the reader a correct notion of the functions performed by the remarkable machine about to be described, and which is entitled to rank with the power press in the important influence which it must exert upon the printer’s art. There have been numerous attempts to do the work of type-setting by mechanical means, there having been granted by the United States Patent Office, up to January 1st of the present year, no less than 160 patents for type-setting and distributing machines, without considering what may have been attempted in foreign countries. The requirements demanded of such a machine, however, are so many, and so severe, that, although a few of these have come into use in isolated situations, their success has until lately been only moderate and questionable, while by far the greater number of them have proved to be utterly worthless for practical use. The machines that have come into use prior to the introduction of the one about to be described, are so few in number as to have exerted no appreciable effect on this important branch of the printing business, and their existence, so far as any promise they hold out of revolutionizing the art of type-setting, may be ignored. The Linotype has a very different history behind it, and a future of high promise before it. The capability of the machine practically to supersede the old and tedious work of type-setting, has been so fully demonstrated in actual service as to leave no room for doubt. For more than two years these machines have been in use in the New York Tribune office, where they have done, substantially, all the work formerly done by compositors; and at the present time they have found their way into the offices of a number of the representative newspapers of the country, and their use is rapidly extending, more than one hundred of them being at the present time in actual service.

It will properly introduce the description of the Linotype, to indicate briefly the causes of the practical failure of antecedent machines of its class. The leading feature in nearly all of these machines preserved the single letter as the unit from which they have proceeded to devise ways and means more or less ingenious and complicated for handling it. In some, the effort has been made to produce the type characters, as they were set up, from the molten metal, which is one of the essential features of the Linotype; but the attempts have been either failures or indifferently successful, for the reason that they limited the operation to the casting of an individual type character—a single letter at each operation. In other forms of machine, the attempt has been made to set up a line, or series of lines, of type characters, which were then forced by pressure into the surface of some medium sufficiently yielding to receive a sharp impression, and resistant enough to permit the impression thus made to be reproduced by the usual stereotype process. This appears to have been the most practical suggestion that was made prior to the production of the Linotype. There appears, however, to have been practical limitations to the usefulness of these machines, the most likely cause of their want of success being that they could not be operated with sufficient rapidity and certainty to exhibit any economy over the manual composition.

With these preliminary considerations, we may proceed to the description of the Linotype. The machine, as a matter of course, embodies numerous features which other inventors have sought to put in successful practice, and, to clear the way for its development, the company owning it has acquired, by purchase, a large number of patents embodying’ such mechanical elements as were found to be valuable. The machine which has finally been developed by toilsome step-by-step labor, and as the final outcome of many fruitless and costly experiments, is a product in which many original elements are cleverly combined with pre-existing ones, the whole constituting a compact and ingenious mechanism, which performs its intended functions in the most satisfactory manner — smoothly, rapidly and economically. In a word, it is the realization, for the first time, of a thoroughly practical machine for superseding the slow methods of manual composition, that have remained practically unchanged since movable types were first introduced.

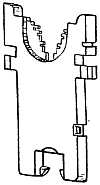

The Linotype is the invention of Ottmar Mergenthaler, of Baltimore. It is not, in the proper sense of the term, a type-setting machine, but represents the means by which a new method of composing is accomplished. In this method, the use of movable types is done away with, and in place of the single letter, the line becomes the unit of composition. To be specific, the machine casts a series of metal bars, each of which represents a single line of printing surface, having the width, length and height of a line of type which the compositor would set up, and forming the exact counterpart of a line composed of single letters, except that it is formed of a single bar of metal, with the letters cast upon its face. When a sufficient number of these have been produced, they are arranged and locked up in the chases precisely like ordinary type, and are printed on the press in the ordinary way. The work of distribution is made unnecessary, as the type bars, after having served their purpose, are thrown into the melting pot, to reappear in new bars. The appearance of one of these type bars constituting the line, which forms the unit of work of the Linotype, is shown by Fig. 1. The width of the type bar will be varied to suit the measure of the column in the page.

The system upon which the production of the type bars depends, has for its basis the employment of a series of small, independent matrices of hardened brass, the appearance of which is shown by Fig. 2. Each of these has precisely the space and thickness which the letter it represents, has in the ordinary type letter of the corresponding font; and in a recess in its edge carries the impression, in reverse, of a letter. This impression forms the mold in which the letter, with others forming the completed line, is cast. The assembling of these matrices to form the line, is controlled by a key-board, before which the operator is seated. His work consists in manipulating the proper keys, and when a line is completed, delivering it by a movement of a lever to the casting mechanism. Beyond this, no manual labor or thought is demanded, and all the operations of the machine—the justification of the assembled line of matrices, the casting and finishing of the line, and the return of the matrices, after they have performed their office, to their respective receptacles—are performed automatically.

The machine, therefore, has three principal functions to perform: (1) The assemblage of the matrices to form the type bar; (2) the casting of the type bar; and (3) the return of the matrices to their respective compartments. Of these, the second and third are performed automatically, the first only being subject to the control of the operator; and, considering how irregular and complex the movements are which the machine is called upon to describe, and which it performs with unfailing accuracy, the result is a remarkable triumph of inventive ingenuity. It will be most convenient, in considering the mechanical details of the Linotype, to begin with the key-board. This consists of four or more banks, carrying in all 107 keys, each of which is marked to represent one of the capital or lowercase letters, figures, points and compound letters which constitute a font of type. In front of the operator, and just above the key-board, is placed a convenient frame for holding the copy. Above and behind this many be observed a row of vertical tubes, which serve as magazines for holding the matrices. Each of these magazines is the receptacle for a certain letter or character, and by an ingenious contrivance, operating automatically, none can enter it but those for which it is intended. The keys are pivoted in a supporting frame carried by a bar attached to the magazine tubes, and each is provided with a vertical slot, through which a matrix falls by gravity when the key controlling it is depressed, another matrix at the same time descending from the magazine tube to take the place of the one discharged. The slotted key, therefore, through the intervention of the operator serves the purpose of receiving and controlling the delivery of the matrices, one at a time. The magazine tubes are drawn from sheet metal, making a smooth, seamless conductor, each accurately gauged in size to receive its own particular matrix, and to permit of its passage through it without danger of stoppage. The tubes are slightly flared at their upper extremities, to allow the matrices to enter more freely; and each of them may he removed independently of others should an accidental obstruction render it necessary. The delivery of the matrix follows instantaneously upon the depression of its corresponding key. The matrices (Fig. 2) are formed of thin plates of brass, 1¼ inches long by ¼ of an inch wide. The thickness of each is accurately defined by that of the letter or character which it carries, amid, of course, all the matrices corresponding to the same letter or character are exact duplicates of one another. Each matrix has suspending shoulders, and a recess in the bottom, which serve the purpose of permitting them to be supported upon rails in an inclined channel, into which they are delivered one at a time from the magazines. On these rails the matrix is supported by the shoulders in a vertical position, being further prevented from tipping by a pair of piano wires which engage with the opening in the bottom, and thus supported, slide down the incline to the place of assemblage, this action being accelerated by means of a blast of air directed into the channel through the tube seen at the right in the perspective view shown on the first page. The notch in the side of the matrix, on the casting face, above the shoulder, is at the same distance above the shoulder for the matrices of each font, but this distance is slightly different for each of the other fonts. This slight difference is sufficient to prevent the confusion arising from the accidental mixing of matrices of different fonts, since the matrix with the misplaced notch will be arrested, by a corresponding ward, in the path of travel of the matrix to the distributing mechanism hereafter to be described. The triangular notched recess in the top plays an important role in the automatic distribution of the matrices to their appropriate magazines, as will shortly appear. This series of notches is different for every letter and character of a font, but is the same for the same letter and character. The position of a line of matrices when undergoing the operation of casting is seen in Fig. 3, at A.

In order that the operator may be sure that no errors have crept into his line, each matrix is provided on its upper face, with the proper character indicated. The whole line, when assembled, is in plain view, and may be read at a glance. Errors are corrected by hand; a transposed letter may be shifted; a wrong letter taken out, and the right one substituted by striking the proper key, which delivers it at the foot of the inclined channel, from which it may be taken and inserted in its proper place in the line. By glancing at the line as he builds it up, the operator also observes how to fill it properly, and how to divide a word when it breaks over the line. The spacing between the words is done by the introduction of a space key of peculiar form, shown in Fig. 4. These are tapering or wedge-shaped strips 8 or 4 inches long, which are inserted between the matrices with their thin ends uppermost, the thick portion of the wedge depending some distance below the bottom of the line of matrices. When the operator has finished setting a line of matrices and spaces, the movement of a lever dismisses it from all further attention on his part, and he proceeds forthwith to set up another line. The dismissed line of matrices, however, is taken in hand by the machine, the automatic functions of' which now come into action.

The line is first carried a short distance to the left and placed between jaws or clamps which stand slightly further apart than the line is long. The tripping of a heavy weight at the rear of the machine carries up a rod which by means of a mutilated gear revolves a shaft on which right and left hand screws advance clamps on either hand to the exact length fixed upon for the line - that is, to the width of the column. Another weight now actuates a vertically reciprocating plate pressing against the lower ends of the space bars which rise uniformly until the line has been expanded to the full limits allowed by the clamps. In this way the increased space between the words is evenly divided and uneven spacing is impossible. It is not a question of a thick or a thin space, for the wedge-shaped bars automatically adjust themselves to take up evenly the minutest fraction of an inch. Thus by a mechanical artifice, as simple as it is ingenious, is effected with the exactness of mathematical accuracy, the work of justifying the lines, which hitherto has been regarded as the chief obstacle in the path of success.

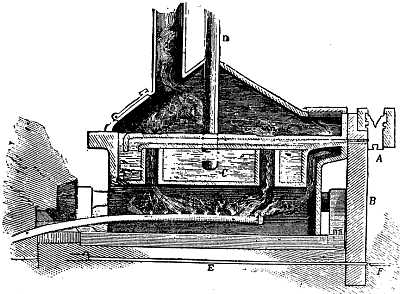

The line of matrices thus completed is received by a head opposite the end of the stationary type guide, there being immediately below and behind the head a mold, in the form of a vertical disk, having a mold chamber or slot extended horizontally through it of a form and size identical with that of the required type bar. This portion of the machine will be better understood by reference to the sectional view, Fig. 3, where B represents the disk mold, A the line of matrices as held up thereto, C the reservoir of melted metal in its gas-heated chamber, D a plunger acting as a force pump to force the metal into the mold, and E an ejector bar which has forced out the type bar F. For the purpose of forcing the line of matrices tightly against the mold, their characters registering with the mold proper, an outside clamping head is employed to bear against the outer edge of the line, while supplemental clamps or jaws assist to hold the line firmly and in exact adjustment. To avoid overheating of the mold when rapidly operated, it is made with transverse openings adapted for communication with the blast nozzle, although no difficulty is ordinarily experienced on this account. The thin type bar made by the machine readily cools sufficiently for ejection during the revolution of the mold disk, the type bars being thence carried to a galley attached to the machine just to the left of the operator, where the bars are assembled in the order of their production in the form of a column ready for immediate use.

But, unquestionably, the most cleverly devised portion of this remarkable machine, is that by which the distribution of the matrices into their proper magazines is automatically accomplished after they have served the purpose of molding the line of type. How this distribution is effected will now be explained:

The whole line rises in the upright guides (frontispiece) at the left-hand side of the tubes, where it meets a pair of rails leading to the endless carrier constantly running over the horizontal framework at the top. At the beginning of the distribution a delicate mechanism comes into play which prevents the passage to the distributer rails of any but nonpareil matrices in a nonpareil machine, agate in an agate machine, etc., and also stops a matrix wrongly faced from passing in. This is accomplished, as has previously been referred to, by a notch upon the real or casting side of each matrix above the supporting shoulders and a corresponding ward in the path of the travel of the matrices. This ward and complementary notch are placed at differing points for the several kinds of type, varying by .031 of an inch for the successive fonts of type. The carrier consists of a steel band, to which is attached cast-iron blocks about three inches long, carrying little brass divisions forming stalls one-quarter of an inch wide. By an ingenious sliding plate one matrix is pushed up into each of these stalls, being held there by two reciprocating fingers which are thrust under the shoulders on which it slides down the inclined channel under the tubes, until the carrier has advanced one space of a quarter-inch, when it is delivered upon the distributer-bar described below. The space bars are not turned over to the carriers, but by a nice discriminating device the same mechanism which shoves the matrices up carries the space bar's down into their box. The details of the distribution are most ingeniously worked out. The carriers have an intermittent motion, progressing a quarter of an inch and then pausing. After leaving the fingers which held there in the stalls, the matrices encounter a steel distributer-bar (Fig. 5) triangular in section, having its two lower sides scored with little rails, which change in their order every quarter of an inch. In a complementary triangular notch in the top of each matrix are inwardly projecting teeth on some one or more of the six levels, which, engaging with the projections on the distributer-bar govern automatically the assorting of the matrices. There are a sufficient number of these notches readily to allow of all the permutations desired, and the distribution is therefore automatically carried on. Only over its own tube does each matrix find no supporting projections under its set of teeth, leaving it free to drop into place. The matrices may be distributed at the rate of about 200 per minute, if so many are used in forming lines in that time. An electric alarm is introduced at this point to indicate to the operator that the work of distribution progresses smoothly. The brass stall divisions and the heads of the brass tubes are connected with wires from a battery. A matrix forced or dropped out of place, or which fails to fall properly into its tube, will close the circuit, and before the distributing apparatus can be clogged, an electric clutch on the main shaft will be thrown out, and the whole mechanism stopped, until started again by the operator.

It may be stated at this point, that a line may be duplicated in casting one or several lines, by which means the expense of stereotyping may largely be avoided. Furthermore, the charge for "standing matter," frequently an onerous one, is eliminated by the machine.

| THE TRIBUNE COMPOSING ROOM. STATEMENT FOR WEEK ENDING WEDNESDAY,

APRIL 10, 1889. |

||||||

Name. |

Amount Set. |

Amount Paid. |

Cost per 1,000. |

Would Cost at 50 cts. |

Am't Saved. |

|

| Adams | 136,000 | $18.00 | 13.2 | $68.00 | $50.00 | |

| Allen | 112,000 | 16.65 | 14.8 | 56.00 | 39.35 | |

| Babcock | 108,000 | 10.85 | 10.0 | 54.00 | 43.15 | |

| Balls | 192,000 | 25.00 | 13.0 | 96.00 | 71.00 | |

| Bulsman | 163,600 | 25.00 | 15.2 | 81.80 | 56.80 | |

| Bevan | 121,300 | 18.00 | 14.8 | 60.65 | 42.65 | |

| Brady | 105,000 | 13.00 | 12.3 | 52.50 | 39.50 | |

| Brandenburg | 158.000 | 26.00 | 16.4 | 79.00 | 53.60 | |

| Bussey | 124,500 | 22.50 | 18.0 | 62.25 | 39.75 | |

| Collins | 155,000 | 26.00 | 16.7 | 77.50 | 51.50 | |

| Cottingham | 126,100 | 15.80 | 11.8 | 63.05 | 47.25 | |

| Dunlap | 151,000 | 26.00 | 17.2 | 75.50 | 49.50 | |

| Good | 129,800 | 12.00 | 9.2 | 64.90 | 52.90 | |

| Hammel | 160,000 | 26.00 | 16.2 | 80.00 | 54.00 | |

| Henry | 98,000 | 12.00 | 12.2 | 49.00 | 37.00 | |

| Hudnut | 98,600 | 15.00 | 15.2 | 49.30 | 34.30 | |

| Jarvis | 157,000 | 25.35 | 16.1 | 78.50 | 53.15 | |

| Jolly | 119,600 | 28.50 | 19.6 | 59.80 | 36.80 | |

| Kulln | 150,000 | 26.00 | 17.3 | 73.00 | 49.00 | |

| Kitcham | 135,300 | 18.00 | 13.3 | 67.65 | 49.65 | |

| McComack | 155,000 | 26.00 | 16.7 | 77.50 | 51.50 | |

| McFeeley | 134,000 | 26.00 | 19.4 | 67.00 | 41.00 | |

| Miller, J | 169,000 | 26.00 | 15.3 | 84.50 | 58.50 | |

| Miller, T | 134,000 | 25.50 | 19.0 | 67.00 | 41.50 | |

| Mills | 169,000 | 25.00 | 14.7 | 84.50 | 59.50 | |

| Shike | 149,000 | 23.50 | 15.7 | 74.50 | 51.00 | |

| Stack | 134,600 | 25.75 | 19.1 | 67.30 | 41.55 | |

| Tyler | 145,000 | 26.00 | 17.1 | 76.00 | 50.00 | |

| VanLeer | 133,000 | 23.25 | 17.4 | 66.50 | 43.25 | |

| Vincent | 116,000 | 10.80 | 9.3 | 58.00 | 47.20 | |

| Wardell | 140,900 | 25.00 | 17.7 | 70.45 | 45.45 | |

| Wells | 120,000 | 15.00 | 12.5 | 60.00 | 45.00 | |

| Wooley | 152,000 | 26.00 | 17.1 | 76.00 | 50.00 | |

| ———— | ——— | —— | ———— | ———— | ||

| Total | 4,557,300 | $704.45 | $2,277.65 | $1,575.20 | ||

| Average | 138,100 | 15¼ | ||||

From what has preceded, the reader will have been able to obtain a fair idea of the various operations, which this remarkable machine performs. Of its entire practicability, from a commercial standpoint, there is no longer room for doubt. The Mergenthaler printing machine has been in use in the New York Tribune office for more than two years, and during much of that time has done, and is at present doing, practically all the work formerly done by the compositors on that paper. At present, we are informed, there are more than one hundred of these machines in service in the offices of prominent newspapers and publishing houses throughout the country, and the demand for them is growing so rapidly that before the close of the present year this number will be more than doubled, if the capacity of the factory will be sufficient to turn them out as fast as they are called for. The machine is not, of course adapted for the production of job or display work, and in the offices where it is in use, the head lines, and other work of this class, are set up by hand in the old style; but for plain copy, such as makes up the great bulk of newspaper, book and pamphlet work, the machine is admirably adapted, and in this field its success has been signal and unqualified.

Upon the question of comparative cost of work by hand and machine, the data afforded by the uninterrupted daily use of the Linotype in the composing-rooms of the Tribune, the Louisville Courier-Journal, the Louisville Daily Times, the Chicago Daily News, the Providence Journal, Providence, R. I., and other large offices, during the past six months, have proved that the cost of producing letter-press forms, ready for the press, does not exceed one-third that of hand composition. In proof of this, we reproduce, in the accompanying table, a specimen record of work done and wages earned in one week in the Tribune office, which represents the work of thirty-three men on as many machines. This record is by no means as good as some that might have been chosen, but, on the contrary, is an average exhibit of a week’s run.

The work done by the 33 men operating the machines, is the same as that which previously required the services of 90 compositors. The actual saving to the Tribune per week, as exhibited by the table, is nearly $1,600. As an argumentum ad crumenam, this exhibit (an average one, be it remembered) is unanswerable, and it is not hazarding much to predict that ere long every considerable newspaper and publishing office will be forced, by the inexorable law of self-preservation, to introduce these machines, if they would maintain their existence in competition with those which use them.

The time and labor required to learn to operate the machine are inconsiderable. It is no more difficult to acquire the necessary manipulative skill to use it speedily, than to learn the art of operating a type-writer, which any one of ordinary capacity may acquire by a few weeks of constant practice.

The Mergenthaler Printing Company, which owns the patents covering the Linotype, has its office in the Tribune Building, New York. The company has a large factory for manufacturing the machines, at 20 to 24 Ryerson street, Brooklyn, N. Y. The equipment of this establishment is on a scale of considerable magnitude arid is very complete, every detail of the work, from the production of the steel punches or dies for impressing the letter into the matrices, the stamping of the matrices, the foundry and machine work, and erection, being done on the premises. In the production of the steel punches, special processes, involving the use of specially devised instruments of precision, are employed. An interesting feature, illustrating the thoroughness with which the establishment is organized, is the school of instruction for beginners, a number of finished machines being constantly on hand for this purpose.

To recapitulate, the Linotype is a machine which has demonstrated in actual service its capabilities as a thoroughly practical substitute for the manual labor of composition. Although performing a number of functions, the mechanical details have been so ingeniously worked out, that tine liability to derangement is reduced so low that it may be ignored as a disturbing element—a single machinist being sufficient to keep the forty machines of the Tribune in working order; and in respect of the cost of operation, it has demonstrated, as the result of continuous service extending over two years, an economy of 66 per cent as compared with the manual labor which it is destined ere long to replace, wherever the pressure of its competition shall be felt. We may state, in conclusion, for the information of interested parties, that the company does not intend to sell its machines outright, but to lease them, on the basis of a fixed rental.

- Science Quotes by Ottmar Mergenthaler.

- 11 May - short biography, births, deaths and events on date of Mergenthaler's birth.

- The Linotype - Manufacturer and Builder Magazine Article (Jun 1889) - Frontispiece

- Mergenthaler’s Speech - after exhibiting his Linotype invention in Washington D.C. (1885).

- Today in Science History short event description for first Linotype machine put in service on 1 Jul 1886.

- The Biography of Ottmar Mergenthaler, Inventor of the Linotype, by Carl Schlesinger (ed.). - book suggestion.