(source)

(source)

|

Stephen McCormick

(26 Aug 1784 - 28 Aug 1875)

American inventor and manufacturer who invented and manufactured a practical cast iron plow with detachable components. His was an early use of standardization of replaceable parts which led to the development of improved manufacturing processes.

|

To all whom it may concern:

Be it known that I, Stephen McCormick, of Auburn, in the county of Fauquier and State of Virginia, have made certain improvements in the plow for which I originally obtained Letters Patent of the United States dated the 28th day of January, in the year 1826; and I do hereby declare that the following is a full and exact description of the improvements for which I now solicit Letters Patent.

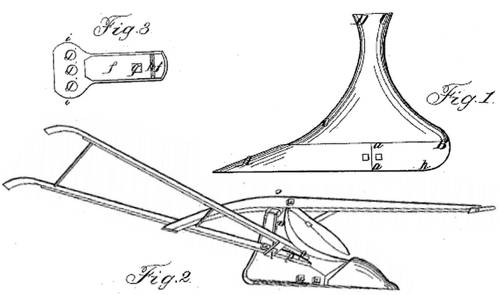

Figure 1 is a representation of the form which I give to the landside of my plow. Its length from A to B is eighteen inches, or nearly so. The landside and mold-board I have cast in one entire piece, as is frequently done in other plows. The share may be of wrought or of cast iron. Upon the lower side of the landside there is a rabbet or recess to receive the hind end of the share, when of wrought-iron, which is to be screw-bolted to and flush with it. This recess may be two inches in height. Its line of junction at the back end is shown at a a. On the lower side of the landside, at its back end, I also generally form a recess or rabbet, the place of which is shown by the lines a a B, to receive a shoe, which is to be bolted on. Sometimes, however, I omit the shoe and leave the casting solid, and in the form shown in the drawings. From the back end of the mold-board, as at b, at the distance of about five inches from B, its bottom line rises in a gentle curve, but as it approaches the heel the curve is quicker, and the heel assumes a semicircular form, as shown in its outline at B, which semicircle is upon a radius of about two inches. This curvature in a landside of the designated length gives a proper leverage to the handles, while it suffices to steady the plow, keep it in its proper forward direction, and counteracts the action of the earth against the mold-board in its turning. The back edge of the landside, from the heel B to the top C, which bears against the beam, rises in a curve inclining toward the front, the curve being identical, or nearly so, with that of the front or cutting edge of the mold-board c D.

The handles of the plow are at their inner ends brought together, so as to be fastened to and between the mold-board and landside, at about half the height between the bottom of the landside and the beam, as shown in Fig. 2, where the plow is represented as turned bottom upward, where d d are the ends of the handles and e a screw-bolt, which draws them upward against ledges cast on the landside and mold-board to sustain them, the bolt e passing up through the beam and confining the whole together. By this plan the inner ends of the handles are removed out of the influence of the friction and clogging of the earth, grass, &c.

The clevis which I use is of an improved form, and is made of cast-iron. It is represented separately in Fig. 3. It may be fixed either to the top, bottom, or side of the beam. The portion f f, by which it is fastened to the beam, is concave on its inner side, and should be in the concave part about five inches in length and about two and one-half inches wide. It must be fitted to the end of the beam, and to check any tendency to being drawn forward it has a ledge or ridge across it at h, which is let into the beam. A single screw-bolt passing through the hole g and through the beam confines it securely in place. The bolt does not pass directly through the beam, but is inclined back toward the plow, so that in straining the nut it tends to draw the clevis back, and resists the forward draft the more perfectly. The head and nut of the bolt, of course, have bearings which adapt them to the position of the bolt. The end i of the clevis I make about two and one-half inches from the concave to its front edge and about four and one-half inches wide. There may be three holes in it, j j j, three-fourths of an inch in diameter, the holes and end being rounded and having in thickness the substance of metal of about an inch each way.

What I claim as my improvements in the plow, and wish to secure by Letters Patent, is—

1. The curved form given to the heel of the landside, and also the concave form of its back edge as it rises from the heel to the beam, as herein set forth.

2. The manner of stocking the plow, so far as the fixing of the handles is concerned, by causing their inner ends to meet about midway between the bottom of the landside and the beam, and confining them there in the way described.

3. The cast-iron clevis, formed and attached to the beam, substantially as herein set forth--that is to say, embracing the beam by its concave part, and having a ridge let into the beam, and the bolt inclined backward to resist the direct action of the draft.

W. Thompson.

- 26 Aug - short biography, births, deaths and events on date of McCormick's birth.

- Stephen McCormick - Biography

- Stephen McCormick, U.S. Patent X3063 (3 Feb 1819) - the first patent on his plow.

- Stephen McCormick, U.S. Patent X4325 (28 Jan 1826) - the second patent on his plow.