(source)

(source)

|

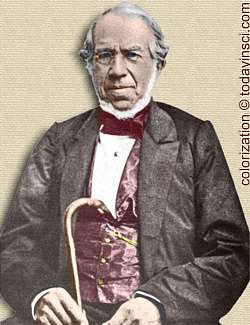

Thomas Blanchard

(24 Jun 1788 - 16 Apr 1864)

American inventor who made major contributions to the development of machine tools.

|

THOMAS BLANCHARD

from Leading American Inventors (1912)

[p.104] Seventy years ago a great triumvirate, Clay, Calhoun, and Webster, were the idols of America. Their portraits adorned parlors and offices, courtrooms and capitols, from one end of the Union to the other. Here and there an admirer, more prosperous than his neighbors, had a bust of one of these worthies on his mantelpiece. The continuing remembrance of these great leaders is due in no small measure to the thousands of pictures and effigies thus set up throughout the country, and still to be found in many a farmhouse and mansion of South Carolina, Kentucky, and New Hampshire. We may feel certain that all three statesmen grew at last thoroughly tired of posing to artists, so that they rejoiced at a reprieve, at least so far as sculptors were concerned. This was promised one morning in 1840, as Clay, Calhoun, and Webster were invited to view busts of themselves copied in wood by a cheap and simple process. These figures, beautifully executed, awaited them on a table in the rotunda of the Capitol. Beside them stood Thomas Blanchard, who seemed truth incarnate, so transparent was his eye, so straightforward his speech. Yet he said that these admirable busts had been carved on a lathe of his invention almost as readily as so many gunstocks. This machine he had invented and patented long ago, but only that year had he built it on lines delicate enough to reproduce statuary. Its chief business, indeed, had been to shape stocks for guns, handles for tools, lasts for shoes, and tackle for ships. Pirates had been so numerous and active a band, that this wonderful machine had brought its inventor but little reward. He had, therefore, come to Washington to ask from Congress a favor without precedent,— [p.105] a second renewal of his patent. In the Capitol, beneath the table where he displayed his busts, was a basement room where the inventor showed his lathe as it repeated in oak the classical features of Washington. As the principle of the machine came clearly into view, Webster exclaimed: “How simple it is, after all!” Blanchard, thanks chiefly to Webster, was accorded a third term for his patent, on the ground of the high utility and singular originality of his invention, and in view of the inadequate return he had derived from it. Rufus Choate, the eminent jurist of Boston, who opposed the inventor’s petition, could only say: “Blanchard has ‘turned the heads’ of these Congressmen, so we need not wonder at his victory.” Sculptors, day after day, came to view the Blanchard machine. In their own reproduction of a bust they were obliged, from moment to moment, to take precise measurements, repeating each dimension with anxious care. That such a task should be performed by a self-acting cutter was simply amazing.

Blanchard’s lathe, as it first left his hands, remains the core of its successor to-day. Its principle flashed into his brain because among the prime resources of his workshop were revolving cutters. Let us retrace a few of the steps which led to these marvelous tools. Knives or chisels were doubtless in their first estate mere flints, or bits of shell, to divide a fish or a bird into morsels, to hack a root or a tree, to sever a hide into thongs. Much more recent than the knife is the wheel, which probably began work as a round log turning beneath a burden dragged on the ground. When knives were joined with wheels, their union at once conquered a vast field forever denied to simple knives, or mere wheels, by themselves. This union was prophesied as soon as a stone was rounded into a wheel, mounted on an axle, and bidden to grind blades of iron or bronze. From that contrivance are descended all the grindstones of today, and the wheels of emery, corundum, and carborundum, [p.106] ablaze in ten thousand machine shops at this hour. But every such wheel has its appointed limits: it removes iron or steel, copper or brass, particle by particle. In a much wider province of shaping, the tasks are bolder and the pace swifter. A wheel armed on its rim with steel cutters, as in modern milling machines, sweeps off a thick shaving or even a goodly slice. Revolving cutters, much simpler than these, were used to plane iron by Bramah as early as 1811. Cutters quite as keen and strong were in daily use by Blanchard for years. In his lathe he broadened their scope by nothing less than a leap.

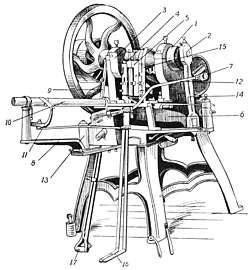

Let us look at his machine as it produces a gunstock. On an axle slowly revolved are placed a stock to be copied and a wooden block in every way larger. Parallel to this axle is hinged a rectangular carriage, sliding gradually from one end of the lathe to the other. A spindle forming the outer boundary of this carriage may freely swing through a wide arc: it carries two wheels of like diameter, about three feet apart. One of them, pressed by a weight or a spring against the rotating stock to be copied, is small enough to touch its every point. The second wheel has at its rim a score of sharp cutters. As the first wheel feels its way along every contour of the original stock from end to end, its path is duplicated by the cutting wheel, which removes wood enough from its block to leave behind a copy of the model stock. When once the lathe is duly set and started, its work proceeds to a finish without a touch from its attendant. His task, therefore, is much easier than when he copies a simple diagram with a pantograph, for then he has to trace with his fingers the whole course of every copied line. Strange that to reproduce a figure of three dimensions should be less trouble than to copy a figure of but two!

Thomas Blanchard, the inventor of this wonderful machine, was born in Sutton, Worcester County, Massachusetts, [p.107] on June 24, 1788. His ancestors, of mingled French and English blood, were among the first settlers in that vicinity. His father, Samuel Blanchard, was a hardworking, thrifty farmer. How large a family he had we do not know, but of his six sons, Thomas was the fifth. This boy’s talent for building and contriving was manifest almost from his cradle. At ten years of age he whittled from cedar shingles a tiny mill, to be impelled by a breeze or a brook. The poor fellow stammered badly, and this brought him much thoughtless ridicule. At school he was shy and seemed backward: it was ever with joy that he dropped his slate and copybook to take up a penknife and chisel. His father, though a Yankee, cared little about tools and machinery, and he glanced without interest at the handicraft of his ingenious boy. Nor was there much else in the neighborhood to nourish the budding powers of this young mechanic. The nearest blacksmith’s shop was six miles off, and it was but seldom that his father went there. Thither Thomas was taken one day to see a horse shod. This feat, new to the boy, he watched with both eyes. What most amazed him was to see the smith weld two pieces of iron as if mere dough on a baking-board. Why not repeat this marvel at home?

Near his father’s house was a shed, once used for weaving, and now encumbered with hoes and harrows, plows and spades, old and new. In one corner of its attic lay a heap of scrap iron, from which the lad chose pieces likely to be serviceable. With stones and bricks gathered from the farmyard, he built a forge, like the blacksmith’s, only much smaller. Fuel was needed next: where was he to get it? When his mother’s back was turned he took coals from her kitchen grate; these, thoroughly drenched, he quietly conveyed to his forge. A big iron wedge, firmly driven into a log, would do for his anvil. When these preparations were well under way, Thomas heard joyful news. His [p.108] father and mother next morning were to visit a friend twenty miles away. Their absence would give him a chance to weld a dozen bits of iron together if he liked. When his parents drove off, he was soon plying a bellows at his little forge. In a few minutes its blaze was fierce enough to soften his metal, so that it took any shape he pleased. But to weld any of his iron scraps proved impossible, for the reason, then unknown to the boy, that his fire was not hot enough. He saw with dismay that he must call a second time on the blacksmith, so as fully to learn an art not so easy as it seemed to be. As the lad stood surveying his darkened lumps of metal, in strode his father, wondering what all this smoke and fire were about. His scolding was qualified by paternal admiration of the spunk and gumption so plainly in view. But it was a good while before Thomas Blanchard undertook his second task at a forge. His father had hoped to make a farmer of him, and when with reluctance, he saw that his son was resolved to be a mechanic, he said: “Well, my boy, learn blacksmithing if you like. Only learn it thoroughly, and never let a job leave your hands unless it is the best you can do.”

While yet a schoolboy, he took his first step as an inventor, holding fast to his father’s injunction of thoroughness. A schoolmate one day told him of an apple-paring machine of lightning pace that he had seen in Boston. Without so much as a hint regarding its construction, Blanchard said: “ I will make one.” Within a week he built a parer of wood and iron, its spindle swiftly rotating an apple as the crank was turned; but its knife at once slid toward the core of the fruit, instead of removing its rind. To remedy this fault, our young inventor took occasion to observe that a hand-parer, by way of gage, always kept his thumb close to the rind he was slicing off. Accordingly he added a gage of wire to his blade, which now pared its fruit just as it should. From that day forward [p.109] Thomas Blanchard was in high favor at paring bees near and far: he could easily peel more fruit than any six rivals together, no matter how quick their fingers and thumbs. His apple-parer taught him a lesson he never forgot: that if a machine is to supplant the human hand, it must faithfully imitate every successive act of that hand.

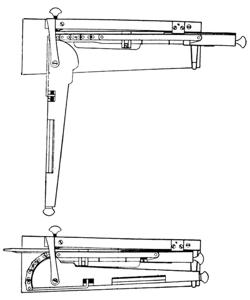

Blanchard’s parer was a hit both social and mechanical, and it gave him confidence to attack devices for work much more serious than apple-paring. At West Milbury, a few miles from Sutton, Stephen, an elder brother, kept twenty boys and men busy at tack-making. He gave Thomas work at a vise, where, hammer in hand, he headed tacks one by one. It was so tedious a task that the lad became disgusted, especially when Saturday night brought him a mere pittance as wages. One of the hands in the factory was employed to count tacks, that they might go into packets of a hundred each. Blanchard devised a self-acting counter, arranging a clockwheel so that it advanced one tooth every time a heading blow fell on a tack. At every hundreth blow, a bell was rung, announcing that it was time to fold up a packet. Blanchard’s brother looked askance at this contrivance, but its inventor was not to be chilled by lack of sympathy. He determined to pass from counting blows to dealing blows, so timed and directed as to produce tacks better and faster than human hands ever did. Machines for this purpose had been brought out long before, but without practical success. A machine that would avoid their faults would be profitable, and this young Blanchard believed he could design. He mentioned his project to his brother, who said: “It takes a knack to make a tack: no machine can do it.”

Blanchard was about eighteen when he began to build a tack-making machine. For the next six years he kept at work upon it at odd times, taking it with him as he went from place to place in a round of factories and shops. [p.110] Whenever he saw how to simplify the action of a knife or hammer, an earlier plan was discarded that very day. When he had reached twenty-four, he felt that he could bestow no further improvement on the thoroughly built model he now showed his family. His machine steadily poured out two hundred tacks a minute, all with better heads and points than those of hand production. His brother Stephen had been sure that tacks of ordinary size, such as fasten carpets, were too small to be shaped by machinery. He was silent when a machine-made tack weighing the one-thousandth part of an ounce was placed on his palm. Blanchard sold his patent for this machine for $5,000. This seemed to him a goodly price: it was a mere trifle for so valuable a property. The purchasers shrewdly marketed their tacks without disclosing that they were made by machinery. As they charged the prices then paid for hand-made goods, their profits were encouraging.

This tack-machine was so well designed that it remains to this day much the same as when it left its modeler’s shop. In Blanchard’s time it was fed by hand: in its modern forms it feeds itself. A single tacker and a quick boy can now mind as many as twelve machines, while keeping their dies well ground and in good order. Blanchard carefully studied the successive operations of making a tack by hand: he then so disposed his levers and wheels, his knives and hammers, that these operations were duly copied, with a force and at a speed far surpassing the possibilities of fingers and fists. First of all, thin plates of steel were divided into strips, each strip as broad as a tack is long. Just enough steel for a blank was then cut off by the contact of two upper knives with a lower bed knife below. In this cut, both upper knives worked as one. As soon as the steel for a tack was cut off, the left-hand knife stopped, and the right-hand knife held the blank by the aid of a steel finger. This finger brought down the blank into the gripping dies [p.112] which closed upon it, while a tool came up and delivered a blow which formed the head. The dies now opened, and a knock-out attachment drove the finished tack into a pan beneath. In modern machines these five operations proceed at the rate of 275 tacks a minute. Fingers of steel do what fingers of flesh had to do a century ago, and with no waste of either metal or motive-power. To-day, as in Blanchard’s time, most tacks have their heads formed by a hammer. If heads of round or other shape are desired, dies of corresponding outline are employed. A minor improvement suggests itself. A little labor would be saved if the metal were fed in continuous rolls instead of in flat sheets.

Blanchard’s success in devising this tack machine brought him fame throughout New England as a man of rare skill and inventive faculty. Naturally enough he soon took part in the quiet revolution then under way in the manufactures of America, where a subdivision of labor, and the production of interchangeable parts, was constantly advancing under the impulse received from Eli Whitney and his compeers. In Milbury, a few miles from his brother’s tack factory, was an armory which produced muskets of high quality. Its proprietor welded his gun barrels under a hammer, and then turned them for almost their whole length on a lathe, leaving about three inches at the breech to be chipped and filed along two flat and oval sides. This task of finishing cost one dollar per weapon, a sum which the gunmaker was anxious to reduce. He sent for Blanchard, and asked him to devise, if he could, an appliance which would mechanically finish his muskets. Blanchard carefully inspected a completed weapon, looked critically at its lathe, and began a monotonous whistle, as was his wont when in deep study. Before the end of that week he had added to the gun lathe a simple cam motion, controlled by a lever, which executed the flats and ovals of a butt with ease and at [p.113] trifling cost. One afternoon, while a journeyman was watching this cam at work, he said to a shopmate: “Well, Blanchard can’t take my job away from me, for I turn gunstocks.” Blanchard overheard this remark, and muttered to himself: “ I am not so sure of that. I’ll think it over.”

There and then the desire to build a self-acting lathe to turn gunstocks took possession of him, and refused dismissal from his mind. Day by day he felt more and more convinced that such a lathe was feasible, and that he was the man to invent it. While manifold schemes for this machine were afloat just below the level of his conscious thought, he was driving homeward through Brimfield, thirty miles from Sutton. In an instant there emerged to his imagination a hinged carriage to hold a feeling wheel, and beside it, a twin cutting and copying wheel. He cried: “I have got it!” Two passers-by heard this exclamation. One of them said to his comrade: “I guess that man’s crazy.” Within a month Blanchard built a lathe which carved so neat a gunstock that it hardly asked a touch from sandpaper. While at Washington securing his patent for this lathe, Blanchard exhibited his machine at the War Department. One of the company was an admiral who inquired jocosely: “Can you turn a seventy-four frigate?” “Yes,” replied the inventor, “if you will furnish a block.”

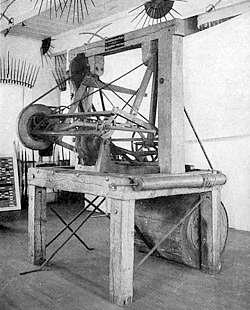

Blanchard next entered the service of the United States Armory at Springfield, Massachusetts, where he erected, in 1822, a large copying lathe, still on view in the Museum of the Armory. It carved two gunstocks per hour. Its successor, much smaller and neater, works nearly six times as fast. In addition to setting up his lathe, Blanchard created or improved at least a dozen machines for the manufacture of firearms. One of these appliances cut square mortises to receive the lock, barrel, butt-plates, and other mountings of a musket. His absorption in all this arduous toil diverted his attention from his chief item of property, the [p.114] copying lathe. This gave a horde of pirates a welcome opportunity; soon more than fifty of their machines were running throughout the country, passing out of Vermont and Maine northward into Canada. To hunt down and punish these thieves was both costly and baffling. The United States Armories at Springfield and Harper’s Ferry paid him a royalty of nine cents for each gunstock turned on his lathes. Apart from these payments, his invention for years scarcely netted him any income whatever. His troubles with rogues began, indeed, before the issue of his original patent. While he was building his first model, he was watched by a machinist who copied his work day by day. When Blanchard reached Washington and applied for his patent, he found that a caveat had been filed on the previous day. But the would-be pirate was foiled, Blanchard, on the morning when he had first tested his model, had called in two witnesses, who noted the date. This precaution secured a just title to the inventor. Of course, his patent did not extend to Canada, so that his lathes taken across the border made lasts by the million, to be exported to the United States free of duty. Blanchard appealed to Congress to have a high tariff imposed upon these wares; after years of delay this was enacted and the importations from Canada came to an end. In its latest form a Blanchard lathe cuts six to ten pairs of lasts per hour, depending upon their size and the finish desired. The five cutters of a last machine are so shaped as to take cuts successively deeper and deeper.

It was in developing the manufacture of shoe-lasts that Blanchard first showed the wide scope of his copying carriage as duly modified. To form a left-foot last from a right-foot last, he caused his pattern and his wooden block to revolve in opposite directions. With equal simplicity he produced from a single pattern a wide variety of lasts, proportionately larger and smaller. He employed copying [p.115] wheels differing in size from the feeling wheel, and differing proportionately, also, in their lengths of path. A Blanchard lathe thus equipped attracted much attention at the Universal Exposition of 1857 in Paris, as it executed in miniature exquisite reproductions of life-size busts of Napoleon III. and the Empress Eugénie. The French admirers of Blanchard recalled, with pride, his descent from a Huguenot of Rochelle, who, with many another refugee, brought rare skill to his new home in America.

Blanchard did not always stay indoors at his work. He was a pioneer in adapting steam to transportation by land and water. In 1825 he built in Springfield a steam vehicle which sped along its highways at a rattling pace, a forerunner of the motor-cars of to-day. It was controlled with ease, turned sharp corners without strain, went forward or backward as readily as a horse, and its power could be doubled when a hill was to be climbed. Blanchard clearly foresaw a great future for railways, with their tracks so much less resistant than roadways. He exerted himself to form a joint-stock company to build a railroad across Massachusetts, submitting his plans, with a model steam carriage, to the State Legislature. On January 23, 1826, its committee reported favorably, but when Blanchard sought to enlist capital, none was forthcoming. He then proceeded to Albany, where he explained his project to Governor Clinton, suggesting that the Empire State should build a comprehensive railroad system, with a line from Albany to Schenectady as its first link. Governor Clinton heard Blanchard with his accustomed courtesy, and told him that his proposal came too soon after the exhausting demands for the Erie Canal. For that great artery the Governor had wrought valiantly for many years. Blanchard was now convinced that the time was not ripe for railroads, and he left their advocacy to other promoters, whose success was not long delayed. While railroading had been in his thoughts, [p.116] he sketched a variety of switches and the like, which were duly adopted when locomotives began their transformation of America.

While railroads had remained merely in the stage of discussion, steamboats had for years been plying with profit the Hudson, the St. Lawrence, and the Mississippi. Blanchard did all that lay in his power to confer a like boon on the Connecticut River. In 1826, the principal business men of Hartford decided to improve the navigation of that stream flowing by their city. Accordingly a canal was built to overcome Enfield Falls, a few miles distant, so that a free channel was opened all the way to Springfield. For the traffic thus offered, Blanchard built the Vermont, the Massachusetts, and other steamers. Of course, he bestowed original features upon them all. In the Massachusetts he employed two steam engines, so coupled as to avoid dead centers at the crank pin. He boldly employed steam at a pressure of 500 pounds to the square inch, aware of the economy attending its use. Of course, to withstand a pressure so extreme he was restricted to boilers of small size. But he found leaks to be unavoidable, and lubrication so difficult at the great heat involved that his experiment was abandoned. Even to-day it would be repeated with hesitation. In 1830, Blanchard designed the steamer Allegheny, to ply between Pittsburgh and Olean Point, 300 miles apart. In this stretch of water there were falls and rapids having a total extent of 600 feet.

In building the hulls of his steamers, Blanchard found the knee timbers, for which he paid a high price, to be sometimes weak and faulty. This led him to examine processes for steaming timbers, and then bending them into forms needed in shipbuilding. He noticed that usually these products were badly cracked and splintered on their outer curves. As the result of many experiments, he designed a machine which bent steamed timbers quite free from fracture. [p.117] Its curved links grasped a stick, while a stout screw firmly pressed the wood against its container. To stretch the fibers of wood, as Blanchard’s predecessors had done, was to weaken them; he employed only compression, which does little harm or none at all. His machine proved to be by far the most lucrative of Blanchard’s inventions. For its applications to ship timbers he received $150,000. It also profitably turned out handles for plows and other farm [p.118] tools, it curved felloes for wheels, it provided slates and pictures with frames much stronger than those made of straight and jointed wood. In this last-mentioned field, small as it seemed, the inventor reaped a harvest which astonished him. A manufacturer of school slates came from Philadelphia one day, and, showing Blanchard an old-fashioned square slate, asked him if he could furnish a frame that would not break apart when let fall to the ground. Blanchard took the slate, chipped off the corners so as to leave it an oval, and then steamed and bent around it an oak strip fastened by an iron loop. The slatemaker let this frame fall to the floor repeatedly, and, finding it none the worse, asked Blanchard his terms for the right to manufacture such a frame for slates. “Two thousand dollars,” said the inventor. “Five hundred is enough,” replied the Pennsylvanian. “Give me five per cent, royalty on your sales,” said Blanchard. His visitor consented, with the result that he paid Blanchard more than two thousand dollars during the first year of their contract.

Blanchard’s income from his patents was now ample, and he removed to Boston. Here, during the remainder of his life, a considerable part of his time was devoted to acting as an expert in patent cases. His intuitive perceptions as a mechanic, his wide and varied experience in machine shops, and his sterling honesty gave unimpeachable value to his judgments. He died in Boston April 16, 1864, at the age of seventy-six.

- 24 Jun - short biography, births, deaths and events on date of Blanchard's birth.

- Thomas Blanchard Biography from Eminent Engineers (1906)

- Thomas Blanchard - seated, large picture, colored.

- Thomas Blanchard Biography - from a A History of American Manufactures (1866).

- Thomas Blanchard - large photo of his original lathe, in the museum at the U.S. Armory, Springfield, Mass.

- Thomas Blanchard - Tack Making Machine - illustration and description.

- Thomas Blanchard - Illustration of Blanchard's Machine For Bending Wood.

- Description of Blanchard's patent - method for bending wood, as used for carriage wheel rims.